CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

FRAMEWORK

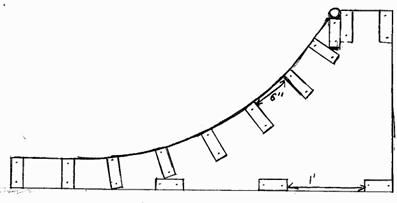

Figure 3 complete frame

- put the trannys together in pairs, so there are now 4 1½ trannys, and in the corner of the deck and the transition, cut a 1½ square

- screw in 1¼ pieces of OSB to the bottom of each tranny structure before you start,(this is for the base and the walls

- cut 1½ off 28 2x4s and screw them in like in this diagram

- cut the leftover 2x4 1 bits that you got from the 7 frame work, and cut yourself 22 3 lengths.

- screw these in 6 apart between the top 2 2x4s (see diagram) and make sure that the 2 side of the 2x4s are facing up(this is the support for the deck

- cut the 8 ft coping down to 7ft

- tape the coping in place with masking tape

- use a 6.5mm metal drill bit, drill holes all the way through the coping (through both sides of the pipe) about 1-inch in on either end of the pipes, as well as in the middle of the pipes, so that both pieces of coping have three holes drilled all the way through them.

- On both pieces of coping, pick one side to be the front or back. On the sides you choose to be the front, use your 13mm metal drill bit to enlarge all three holes being careful not to enlarge the holes on the back.

- Take your long Phillips head screw driver bit and screw the coping into the 2x4s in the coping cradle notch.

- The enlarged holes in the front should allow the screw and the driver bit to get inside the pipe, while the smaller hole on the back should catch the head of the screw and keep it fastened to the 2x4s. Repeat for both sides of the ramp.

- remove the tape

- screw in half of a lock by the edge of each of the tranny walls, in the middle of the transition

BASE

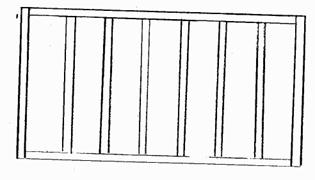

Figure 4 framework for the base

1. cut 1 2x4 in half(making it 4)

2. cut 19 off 2 2x4s(making them 77 long)

3. cut 3 2x4s into 6 44 pieces

4. use the 4 and the 77to make a rectangle, and screw the 6 44 pieces in about 1 apart. It should look something like this

5. screw in a OSB sheet to the bottom(this is to level it out with the walls

Figure 5 framework complete

PLYING

Figure 6 plying the tranny

- now we can ply the 2 halves and the flat bottom. Lay a piece of 4mm ply horizontally across the tranny, and make sure it is just below the coping. Screw this down

- lay another sheet down horizontally and make sure that the top of this sheet is flush with the bottom of the first sheet

- cut off the access which is sticking out

- now lay 1 sheet of 4mm ply on vertically on the tranny structure, and screw it down

- screw down another sheet next to it and cut off the access

- do the same for the other tranny

- screw down 2 pieces of 4mm ply on the flat bottom

- use the access 4mm ply you have cut off from the plying the trannys to ply the decks

Figure 7screwing down the ply

HINGES

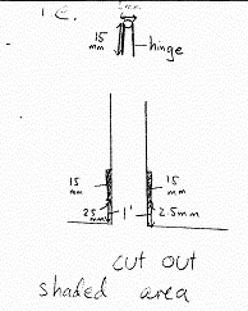

Figure 8 hinge detail

1. measure the diameter of the round bit of your hinge(h)

2. measure the length of the flat bit (LFB)

3. 1 in from the edge of the tranny wall and the flat bit measure a box that is LFBxradius of h

4. now measure the width of the flat bit of the hinge(WFB), and make the box go down as long as the WFB is

5. chisel this box out

6. do the same for the other 3 corners of the tranny, and the other 3 corners of the flat bit and then screw in the hinges

7. test to see weather the hinges work

DOOR

- join the 2 doors you cut earlier together, and then fit them into place

- do the same with the other doors

ROOF

- fold the ramp up, and on top of the structure, lay down 2 sheets of OSB.

- draw around these with a pencil

- on the outside of this line screw in some leftover 2x4s and make sure that there is at least one on each side where the pieces of OSB join

These were my original plans

Figure 9 tom pumping the ramp

Figure 10 josh pumping the ramp

Figure 11 tom stack on the ramp

Date: 2015-01-02; view: 1308

| <== previous page | | | next page ==> |

| MATERIALS | | | HOW TO MANAGE THE MANAGERS |