CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

COMING TO A WINDOW NEAR YOU

Self-cleaning glass does not clean a surface instantaneously – it operates continuously as the window is exposed to natural sunlight and rainfall. The coating cannot be applied to existing windows because it is deposited during the manufacture of the glass itself. However, once Pilkington Activ™ has been installed, after a short 'running in' period, which allows the coating to absorb enough ultraviolet radiation to start working properly, the durable coating will last for the lifetime of the glass.

Pilkington Activ™ is the latest in a line of innovations from Pilkington, including fire-resistant glass (Pilkington Pyrostop), and Hotscreen-glass embedded with tungsten wires, finer than a human hair, that can defrost an icy windscreen at the touch of a burton. In July 2001, the research scientist who headed the team that pioneered the development of Pilkington Activ™, Dr Kevin Sanderson, won the prestigious Worshipful Company of Glass Sellers’ “Award of Excellence”. In agreement, homeowners everywhere are certain to be celebrating as the new glass appears in window products across Europe (Figure 3) and the window-cleaning chore becomes a thing of the past.

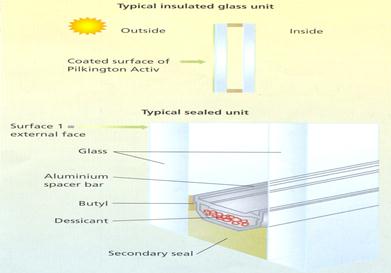

Figure 3. Typical sealed unit of Pilkington Activ™ product for a window.

BOX 1 Glass manufacture — the float glass process

The float glass process is the principal method of producing flat glass throughout the world. The silica and other added chemicals (the 'batch') are melted at white heat (~ 1600°C) to a highly viscous consistency, and held in a controlled atmosphere long enough for the surface to become flat and parallel. The red-hot glass flows onto a mirror-like lake of molten metal and spreads into a thin ribbon. The ribbon is cooled as it flows down the molten metal (the 'float bath') and gradually solidifies into place (at about 600°C). This is now 'float glass'.

Coatings that change the properties of the glass can be applied to the cooling ribbon of glass. On-line chemical vapour deposition (CVD) is the most significant advance in the float glass process since it was invented. CVD occurs following the reaction of gases in a chamber, the products of which deposit on and adhere to the glass substrate.

Date: 2015-01-29; view: 1526

| <== previous page | | | next page ==> |

| PAVED WITH TITANIUM | | | CARBON NANOTUBES AND GENERAL ELECTRO-OP TO-MECHANIC PROPERTIES |