CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Brief history of wool metrology

The application of metrology in wool processing goes back more than two centuries. The first recorded attempt to objectively measure wool’s most important characteristic, fibre fineness, was in 1777, when Daubenton measured the width of some wool fibres under a microscope by comparison with lines drawn on a piece of quartz.

During the 19th century and the first half of the 20th century, the microscope became the favoured instrument for directly determining the fineness of wool tops. For various reasons this technology could not be readily applied to the same measurement in greasy wool.

The development of core testing in the USA after 1937, by the USDA, US Customs and the Boston Wool Trade Association, made the representative sampling of bales of greasy or scoured wool possible.

In Australia in the 1950’s and early 1960’s CSIRO developed manual pressure core equipment. CSIRO and Australian Wool Testing Authority Ltd (AWTA) together with New Zealand Wool Testing Authority (NZWTA) designed improved machine core testing equipment suitable for large volume sampling. During the 1970’s the Australian Objective Measurement Program (AOMP), as a prerequisite to “sale by sample”, developed systems for representative grab sampling of full length wool from greasy or scoured wool lots.

These improved sampling technologies opened the way for the development of Standard Test Methods, which were able to provide more accurate and precise estimates of the most important value-determining characteristics of greasy wool in mill consignments, namely:

· Wool Base (Yield)

· Mean Fibre Diameter (Micron)

· Vegetable Matter Base

· Mean Staple Strength

· Mean Staple Length

· Colour

It is important to remember that these parameters are those previously subjectively assessed by wool buyers and by mill technicians before the advent of modern measurement technologies. Traditionally the industry has used these parameters to predict the value determining characteristics of wool tops such as:

· Mean Fibre Diameter (Micron)

· Hauteur

· Coefficient of Variation of Hauteur

· Colour

The major breakthrough in wool metrology occurred in the period 1945 to 1955 with the development of the Airflow instrument. This provided a relatively inexpensive indirect method for measuring the fineness of tops. By the late 1960’s methods for preparing and measuring the fineness of greasy wool by Airflow had also been developed, and this instrument, despite its known limitations, became the primary technology for measuring the fineness of wool.

In the UK, WIRA Instrumentation Ltd and the British Wool Federation developed both yield and fineness test methods, but the USA and Europe established different processing and moisture tolerances to estimate commercial yields of fibre obtained from greasy wool.

The international adoption of common sampling and testing procedures became possible through the International Wool Textile Organisation (IWTO), established in 1930. IWTO set up technical and commercial committees to oversee the development of standards, thereby enabling common sampling and measurement processes to be adopted by all wool growing and wool processing countries. Nevertheless, it was not until 1965 that technical and commercial delegates at IWTO were able to agree on standardised sampling and testing processes for Wool Base and Vegetable Matter Base. The industry waited until the early 1980’s for development of standardised systems for determining Staple Length & Strength and Position of Break based on subsamples drawn from grab samples

Once wool metrologists had developed the sampling and testing technologies and Standard Test Methods became available, the impetus for the growth in objective measurement, initially for mill consignments and then for presale farm lots was driven by the users of wool, to assist them in ensuring the quality of conformance of the yarns, fabrics and garments they produced. In Australia wool producers were initially reluctant to adopt objective measurement and sale by sample of auction lots, but adoption accelerated throughout the 1970’s, 80’s and 90’s as price differentials between untested and tested lots became evident.

During the 1990’s new technologies (Sirolan Laserscan, OFDA100) emerged for measurement of the fineness distribution characteristics of greasy wool as well as the mean diameter. By 2000 these technologies had effectively replaced the Airflow.

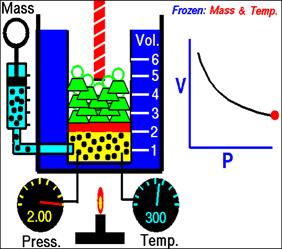

Boyle's law

Boyle's law (sometimes referred to as the Boyle-Mariotte law) is one of several gas laws and a special case of the ideal gas law. Boyle's law describes the inversely proportional relationship between the absolute pressure and volume of a gas, if the temperature is kept constant within a closed system. The law was named after chemist and physicist Robert Boyle, who published the original law in 1662. The law itself can be stated as follows:

For a fixed amount of an ideal gas kept at a fixed temperature, P (pressure) and V (volume) are inversely proportional (while one increases, the other decreases).

Date: 2016-04-22; view: 1238

| <== previous page | | | next page ==> |

| Discuss in pairs (groups) using text A constituent parts of ADC. | | | Find the words. Circle |