CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Furnaces

Coal is the product of vegetable matter that has beenvformed by

the action of decay, weathering, the effects of pressure, temperature and time millions of years ago.

Although coal is not a true mineral, its formation processes are

similar to those of sedimentary rocks.

According to the amount of carbon coals are classified into;

brown coals, bituminous coals and anthracite. Brown coals are in

their turn subdivided into lignite and common brown coal.

Although carbon is the most important element in coal, as

many as 72 elements have been found in some coal deposits, including

lithium, chromium, cobalt, copper, nickel, tungsten and others.

Lignite is intermediate in properties between peat and bitumi-

nous coal, containing when dry about 60 to 75 per cent of carbon

and a variable proportion of ash. Lignite is a low-rank brown-to-black

coal containing 30 to 40 per cent of moisture. Developing heat it

gives from 2,500 to 4,500 calories. It is easily inflammable but burns

with a smoky flame. Lignite is liable to spontaneous combustion. It

has been estimated that about 50 per cent of the world's total coal

reserves are lignitic.

Brown coal is harder than lignite, containing from 60 to 65 per

cent of carbon and developing greater heat than lignite (4,000-7,000

calories). It is very combustible and gives a brown powder. Bituminous

coal is the most abundant variety, varying from medium to high

rank. It is a soft, black, usually- banded coal. It gives a black powder

and contains 75 to 90 per cent of carbon. It weathers only slightly

and may be kept in open piles with little danger of spontaneous

combustion if properly stored. Medium-to-low volatile bituminous

coals may be of coking quality. Coal is used intensively in blast

furnaces for smelting iron ore. There are noncoking varieties of

coal.

As for the thickness, the beds of this kind of coal are not very

thick (1-1.5 metres). The great quantities of bituminous coal are

found in the Russian Federation.

Anthracite or "hard" coal has a brilliant lustre containing more

than 90 per cent of carbon and low percentage of volatile matter. It

is used primarily as a domestic fuel, although it can sometimes be

blended with bituminous grades of coal to produce a mixture with

improved coking qualities. The largest beds of anthracite are found

in Russia, the USA and Great Britain.

WRITING

Task 16

Write an abstract of the text “ Coal and Its Classification” according to the plan:

1. The classification of coal.

2. The characteristic of lignite, brown coal, anthracite

3. The largest deposits of coals in the world

WORDLIST

| available | доступный |

| to concentrate | сосредоточиваться |

| decay | распад |

| to refer to | объяснять, ссылаться, относиться |

| to give off | выделять, испускать |

| to divide | делить |

| manufactured | промышленного производства, искусственный |

| peat | торф |

| plant | растение |

| to include | включать в себя |

| coke | кокс |

| charcoal | древесный уголь |

| commercial | промышленный, коммерческий |

| steel industry | сталелитейное производство |

| tendency | тенденция, стремление |

| to increase | возрастать, увеличиваться, усиливаться |

| raw material | сырье |

| petrochemical | нефтехимический |

| to design | разрабатывать, конструировать, проектировать |

| coal conversion | переработка угля |

| strip mining | открытая разработка |

| to haul | перевозить, транспортировать |

| to drive from | происходить |

| crude oil | сырая нефть |

| to furnish | поставлять, снабжать |

| to refine | очищать |

| pollutant | загрязняющее вещество, примесь |

| distribution | распределение, размещение |

| to promise | обещать |

| extensive | обширный, пространный |

| storage | хранение, накопление |

| compartment | отделение, камера |

| to pipe | пускать по трубам |

| trial | испытание, опыт |

| exhaust | выхлопная труба, выхлоп |

| consequence | последовательность |

| to spill (spilled, spilt) | проливаться, разливаться |

| instantaneously | мгновенно |

| dissipate | рассеиваться |

| emergency | авария |

| to be aware | знать, сознавать |

| damage | повреждать |

| liable | подверженный, склонный |

| reduction | восстановление |

| harmful | вредный |

| eject | выбрасывать, выпускать |

| coal deposit | угольное месторождение |

| peat | торф |

| bituminous | битумный |

| low-rank | низкосортный |

| inflammable | легко воспломеняющийся |

| liable | подверженный |

| lignite | лигнит, бурый уголь |

| lignitic | гумат(для обработки буровых скважин) |

| to weather | подвергаться (атмосферным воздействиям) |

| pile | отвал, отвал грунта |

| blast furnace | доменная печь |

| coking | коксование |

| lustre | блеск |

| blended | смешанный |

| grade | сорт |

Furnaces

TUNING – IN

Task 1

Name the principal function of the furnace

Task 2

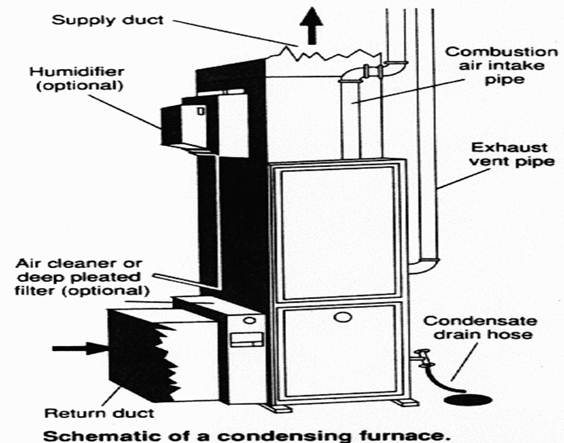

Study the diagram below of a condensing furnace. Answer these questions using the diagram and your own knowledge of engineering.

1. What are the main parts of a condensing furnace?

2. What is the role of condensate drain hose?

3. What is the difference between condensing furnace and non-condensing one?

duct – канал, трубопровод

humidifier – увлажнитель

pleated filter - гофрированный (бумажный) фильтр

intake pipe – впускная (подводящая) труба

exhaust vent pipe – выпускная вентиляционная труба, труба для отбора пара

hose – гибкая труба, шланг

WORDLIST

| 1. to release | освобождать |

| 2. to ensure | обеспечивать, гарантировать |

| 3. gas-tight | газонепроницаемый |

| 4. to pulverize | распылять, размельчать |

| 5. ignition | воспламенение |

| 6. combustion | горение |

| 7. correct | соответствующий, правильный |

| 8. regardless of | несмотря на |

| 9. to maintain | поддерживать, сохранять |

| 10. due to | благодаря |

| 11.to reduce | уменьшать, сокращать |

| 12.to escape | давать утечку, улетучиваться |

| 13.instantaneous | мгновенный, немедленный |

| 14. flame | пламя |

| 15.cyclone furnace | термическая печь с принудительной циркуляцией газа |

| 16.pulverized coal furnace | пылеугольная топка |

| 17.spreader stoker | топка с разравнивающей решёткой |

| 18.chain grade stoker | механическая топка с цепной решёткой |

PRONUNCIATION

Task 3

Remember the pronunciation of the following words

| pulverized | ignition |

| excess | chimney-gas |

| turbulence | effectiveness |

| combustion | absorb |

| instantaneous | cyclone |

| thoroughly | stoker |

WORD-BUILDING

Task 4

Fill in the table

| Noun | Adjective |

| satisfaction | - |

| gas | - |

| combustion | - |

| - | particular |

| - | correct |

| importance | - |

| effect | - |

| - | molecular |

| dependence | - |

READING

Task 5

Read the text and look for answers to these questions:

1. What is a furnace? 2. What does the design of the furnace depend upon? 3. What is the design of a satisfactory furnace based upon?

4. What is the ignition temperature?

5. What is turbulence?

6. What conditions is the required furnace volume dependent upon?

7. What kinds of furnaces do you know?

The design of the furnace depends considerably upon the fuel to be burned. On the other hand, it also depends upon the supplement equipment so that satisfactory ignition and heat release may be ensured.

A furnace is a gas-tight and well-insulated space, in which gas, oil or pulverized coal may be burned. If combustion is to be complete, the combustible gases must be brought into close contact with oxygen. Also, the oxygen must be kept to a minimum and the excess air from room temperature to chimney-gas temperature also is to be low. The design of a satisfactory furnace is based upon the "three T's of combustion": temperature, turbulence, and time.

For each particular fossil fuel, there is a minimum temperature, known as the ignition temperature, below which the combustion of that fuel in the correct amount of air will not take place. If the combustible gases are cooled below the ignition temperature, they will not burn, regardless of the amount of oxygen present. A furnace must therefore be large enough and be maintained at a high enough temperature to permit the combustible gases to burn before they are cooled below the ignition temperature. Thus, the principle function of the furnace is to provide space in which the fuel may be burnt with a minimum amount of excess air and with a minimum loss due to the escape of unburned fuel.

Turbulence plays an important role in combustion. It is the turbulence that gives an effective combustion. Violent mixing of oxygen with the combustible gases in a furnace increases the rate of combustion, shortens the flame, reduces the required furnace volume, and decreases the chance that combustible gases will escape from the furnace without coming into contact with the oxygen necessary for their combustion.

Since combustion is not instantaneous, time must be provided for the oxygen to find and react with the combustible gases in the furnace.

In burning fuels such as gas, oil, or pulverized coal, the incoming fuel-air mixture must be heated above the ignition temperature by radiation from the flame or hot walls of the furnace. Since gaseous fuels are composed of molecules, they burn very rapidly when thoroughly mixed with oxygen at a temperature above the ignition temperature.

The required furnace volume is dependent upon the kind of fuel burnt, the method of burning the fuel, the quantity of excess air in the furnace, and the effectiveness of furnace turbulence. The shape of the furnace depends upon the kind of fuel burnt, the supplement equipment, and the type of boiler used to absorb the energy if the fuel is burnt for steam generation. There are different kinds of furnaces, namely, cyclone furnaces (crushed coal), pulverized coal furnaces, spreader stokers and chain-and traveling - grade stokers.

Date: 2014-12-29; view: 2284

| <== previous page | | | next page ==> |

| Coal and Its Classification | | | VOCABULARY |