CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Comparison with traditional adiabatic and compressor cooling systems

The maximum achievable temperature for the traditional adiabatic coolers is the wet bulb temperature. The larger cooling limit of the Coolerado cooler allows using it in areas and climates where traditional adiabatic coolers are not suitable. In Coolerado cooler there is no change of moisture content in product air. Whereas direct evaporative coolers increase change in moisture content proportionally to the temperature decrease of the product air. Indirect evaporative coolers have some losses in heat exchanger. These losses make the wet bulb temperature unachievable for indirect adiabatic coolers.

After direct evaporative cooler the air has increased moisture content and is almost saturated. But the relative humidity higher than 70% feels uncomfortable /3/. This fact limits the use of direct evaporative cooling in the occupied places. On the other hand Coolerado coolers have its HMX, where working and product air channels are separated. And also the fact that the Coolerado air conditioners have a larger cooling limit than other evaporative systems.

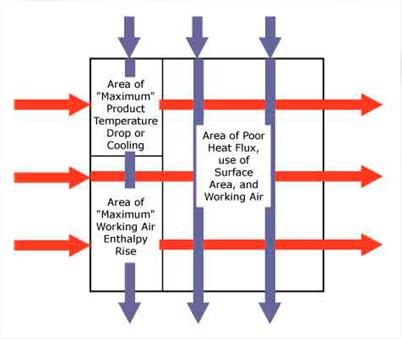

The HMX, which is installed in Coolerado coolers, has much better performance than the most common in indirect adiabatic coolers cross flow heat exchangers (Figure 16).

FIGURE 16. The scheme of the traditional cross flow indirect evaporative cooler /12/

As can be seen from the Figure 16, the highest heat flux occurs at the point where the streams entering the heat exchanger cross with each other. That is the area of the maximum cooling. Area adjacent to the incoming warm air is characterized by the largest increase of the enthalpy of the working air. On the other hand area adjacent to the incoming cold air is characterized by the largest decrease of the enthalpy of the product air. The further the flow of air passes through the heat exchanger, the less heat is transferred from one stream to another. This means that about 70 percent of the cooling is performed by about 10 percent of the working air and 10 percent of the surface area. /12./

Traditional compressor coolers consume a lot of energy. The use of the evaporative cooling systems helps to reduce the energy consumption. Coolerado coolers use up to 90% less energy than the compressor coolers /14/. This significantly reduces expenses for electricity. But evaporative coolers consume water for cooling purposes. In hot weather, the water consumption increases, which can be very important in areas where water prices are high. The average water use for 21,1 kW unit, the Coolerado C60, is about 12 to 15 liters per hour depending on climate and water quality.

Products

Since 2004 Coolerado Company has developed several products. At this moment they have pre-cooling, stand alone and hybrid systems. /15./

Date: 2015-12-11; view: 1800

| <== previous page | | | next page ==> |

| Operation principle | | | Pre-cooling systems |