CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Operation principle

As is known the traditional adiabatic cooling does not allow cooling the air below the wet bulb temperature. However, the use of the M-cycle allows cooling air to lower temperatures. Because of that Coolerado air conditioners, which are based on the M-cycle, were created.

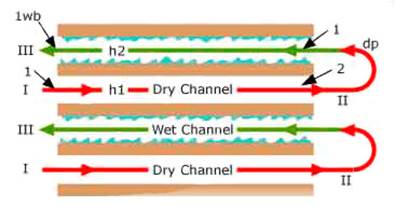

To understand the principle of the M-cycle we consider a simple adiabatic model (Figure 11) /12/.

FIGURE 11. Heat and mass exchanger based on M-cycle /12/

The incoming air comes to the dry channel, where it is cooled by the air flow from adjacent wet channels. In theory, the air in state II is cooled to the dew point temperature of the incoming air I. After that the air stream comes to the wet channel, where due to evaporation it takes heat from the air in dry channels. At the exit of the wet channel the air is saturated and its temperature is equal to the wet bulb temperature. This process can be followed on the Mollier chart in the Figure 12. /12./

FIGURE 12. Adiabatic heat and mass exchange on the Mollier chart /12/

These theoretical results have been achieved in the real prototypes. The air at the outlet of the second channel reached the dew point temperature. But the cooling capacity of this unit equals to zero, because there is no product stream, supply air goes to the outside.

Based on this another scheme was developed for the real air conditioner. Now there are dry channels for the product air and perforation in working channels. This principle was applied in Coolerado air conditioners. M-cycle diagram is shown in the Figure 13 /12/.

FIGURE 13. Perforated cross flow heat and mass exchanger /12/

The incoming air is divided in two streams. The working stream comes to the dry working channel, where it is cooled by adjacent wet working channel. There are also perforations between working channels. They are needed to significantly reduce the pressure drop. Because product channel is isolated from other channels, the air is cooled without changing of the moisture content. Due to this scheme, the product air can be cooled almost to the dew point temperature, which is the theoretical maximum achievable temperature. /12./

Coolerado coolers

Coolerado cooler has a rather simple design. It consists of a fan, filters, Heat and Mass Exchanger (HMX), air and water connections. Schematic illustration of the Coolerado cooler is shown in Figure 14.

FIGURE 14. Schematic diagram of the Coolerado cooler /13/

At first, fresh air enters the system (1). After that, it goes through the filter (2) and enters the Heat and Mass Exchanger (3). There the air flow is divided into two streams. One of them, which is called working stream, takes heat from the other stream, which is called product stream. Humid working air is released back into the atmosphere (4). Chilled fresh air with no added humidity is supplied to the premises (5). /13./

The main part of Coolerado air conditioners is patented Heat and Mass Exchanger (HMX). HMX consists of plates made of a plastic-coated, cellulose blend fiber. This plastic is designed to wick water evenly on one side and and pass well the heat in the transverse direction without mixing of air flows. The plates are stacked on top of each other, and a series of channels are formed between them. The diagram of the HMX is shown in the Figure 15. /12./

FIGURE 15. Design of the Heat and Mass Exchanger /12/.

The air which enters the HMX is divided in two streams. One stream is called working air and another is called product air. Working air comes to the dry channel, where it is cooled by adjacent wet channels. In the dry channel it is splitted into streams which are coming to the wet channels (2). In wet channels the water evaporates and cools air flows of working air. The humid working air is exhausted to the atmosphere (4). The stream of product air enters the dry channel (1), where it is cooled by adjacent wet channels. /12./

Coolerado air conditioners have a modular design. To meet cooling requirements buildings, they may be combined with each other. Capacities in that case are just simply summed. Coolerado coolers can be used as independent air condtitioners and as precooling systems. Also in places, where specific requirements take place, Coolerado hybrid system could be applied. /7, p.2./

Date: 2015-12-11; view: 2300

| <== previous page | | | next page ==> |

| Maisotsenko combustion turbine cycle | | | Comparison with traditional adiabatic and compressor cooling systems |