CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Microstepping setting

Board marked M1M2(match with DIP swtich 3 and 4) to set the value of switching microstepping resolution

| M1 | M2 | Working mode |

| OFF | ON | 1/16 |

| OFF | OFF | 1/4 |

| ON | OFF | 1/2 |

| ON | ON |

Remark:For motor run smoothly, please try to select high segments, such as 1 / 16 microstepping

6.3、current setting:

Board marked T1T2(match with DIP swtich 1 and 2) to set the value of switching current setting

| T1 | T2 | Current |

| OFF | ON | 25%*2.5A |

| ON | ON | 50%*2.5A |

| ON | OFF | 75%*2.5A |

| OFF | OFF | 100%*2.5A |

Proposed current as close as possible stepper motor rated current

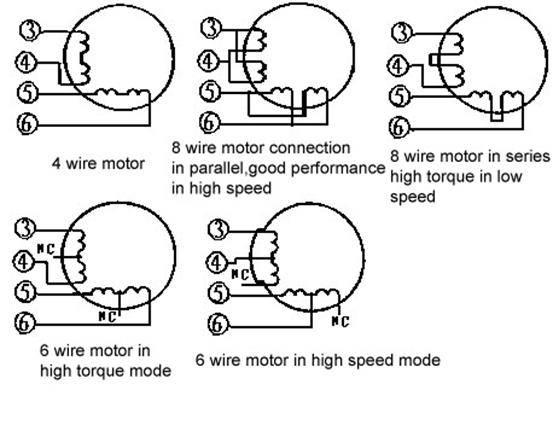

The connection of kinds of stepper motors

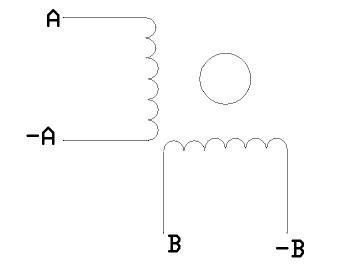

4 lead wires stepper motor:

6 lead wires stepper motor:

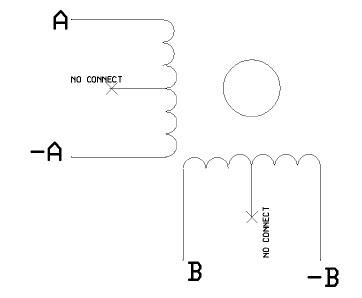

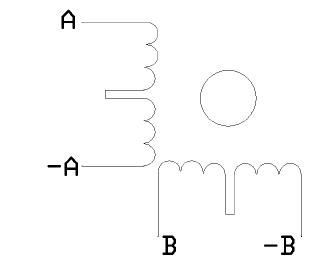

8 lead wires stepper motor:

Stepper motor +A -A +B -B connection AP AM BP BM of board port

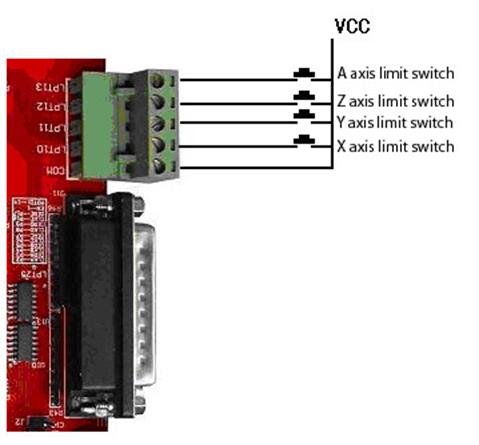

8. The limit switch port connection:

9. The 5th aixs expansion port connection:

10. Drive board and motor match:

The driver can drive two or four phase stepper motors,motor drive in order to obtain the most satisfactory results, need to select a reasonable set of supply voltage and current. The supply voltage level of the decision of the high-speed electrical performance, while the current settings determine the motor output torque.

(1) A supply voltage selected:

In general, the more high of the supply voltage, the more torque in high speed, and able to avoid missing step at high speed. On the other hand, the voltage is too high may damage the driver,also big shock in low speed

(2) output current settings:

For the same motor, the greater the current set value, the greater the motor output torque, but the high heat for motor and driver. Therefore, the general situation is that the current is set to supply long-term work machine when warm but not too hot when the values.

1)when 4 or 6 lead wires stepper motors in high-speed mode: the output current is set to equal or slightly less than the motor rated current value;

2) when 6 lead wires stepper motor in high torque mode: the output current is set to 70% of motor rated current

3) 8 -wire motor connected in series: the output current is set to 70% of motor rated current

4) 8 -wire motor parallel connection: the output current can be set to 1.4 times more than the motor rated current.

Note: The current setting 15-30 minutes after you run motors, such as the motor temperature is too high, it should reduce the current settings.if after reducing the current value, the motor output torque is not enough, please improve the cooling conditions to ensure that motors and drives are not hot.

11. MACH3 software use introduction:

11.1、Mach3 activate:

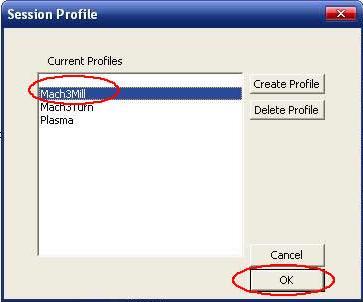

Fig1 open MACH3

Shown in Fig1, open the MACH3 software, and then select mach3MILL then OK!

Fig 2 mach3 main table

Open the MACH3 as Fig2,there are some common buttons,then let us set up it!

11.2、Mach3 software setting:

Fig 3 mach3 setting menu

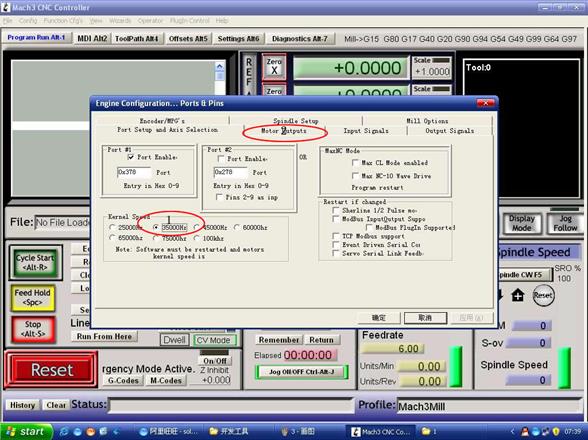

Shown in Fig3, open the CONFIG menu under the PORT & PIN menu.

Fig 4 frequency setting

Circle 1 is for setting the fundamental frequency, this parameter affect the motor rotation speed. Set up and select Circle 2,then will shown in below Fig5 to set up the Pulse and Direction.

Fig 5 The pin setting of Dir,Step

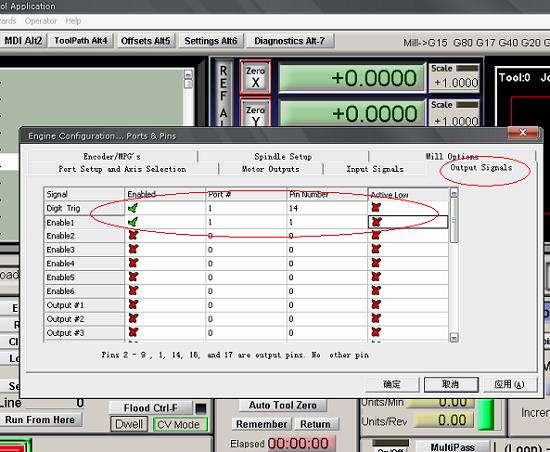

Pls click “output signals” as below Fig6 after set up the Dir and Step to set up the En and Relay.

Fig 6 En and spindle relay Pin setting

11.3、Limit switch mach3 setting:

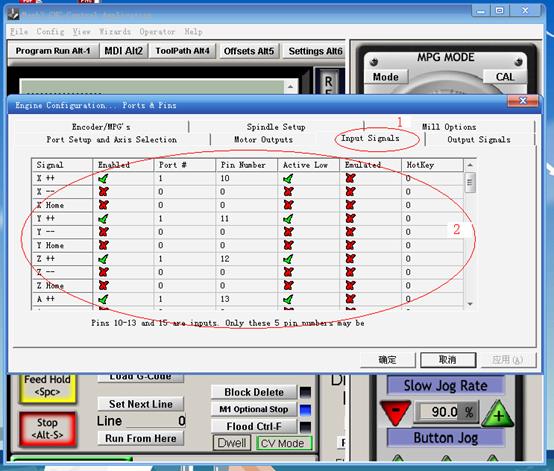

Click “input signal”,setting as Fig7

Fig 7

11.4、G-Code run:

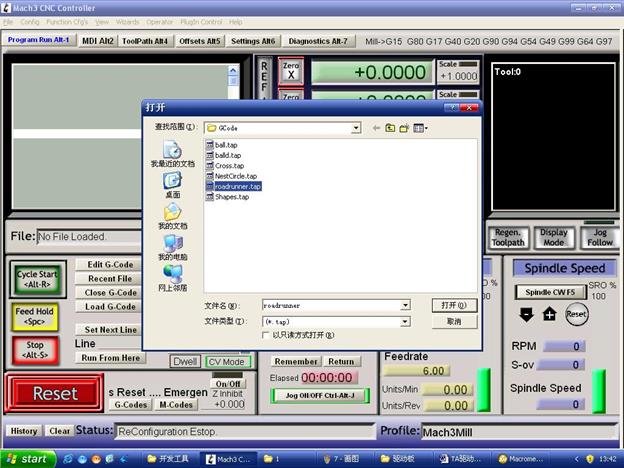

G code is the instruction of CNC procedures,mach3 sofware self with G code for customer testing machine easier,click menu”File” as Fig 8.

图8打开G文件

Click “Load G-code” , then open the file which contain the MACH3 sofware  ,click G code file

,click G code file  to chose a G code as Fig 9.

to chose a G code as Fig 9.

Fig 9 Open MACH3 with self G code testing procedures

Fig 10

Date: 2015-12-11; view: 1919

| <== previous page | | | next page ==> |

| Spindle relay output, easy to use software such as mach3 to control spindle start and stop | | | CALCIUM ABSORPTION: MECHANISMS ANDCONSIDERATIONS |