CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

FINAL CHECKS (SORTING)

The fired product is inspected and classified on the basis of its aesthetic qualities. The number of classes and the adopted criteria respond to corporate marketing needs and, therefore, to demand on those markets on which the company is present In general it can be stated that the product is divided into three classes:

V class: defect-free product, sold at full price;

si1"1 class: product with limited defects that reduce the price to a percentage of that of i* class items;

Reject: product that will be disposed of.

Raising the qualitative yield allows pnxlucers to lower both the fixed unit cost of 1st class products and costs associated with the disposal of rejects.

Testing is carried out by workers at the kiln outlet. Workers must observe strict criteria to prevent subjectivity creeping into the sorting process and the creation of heterogeneous lots that could compromise brand image.

InsjH'Ction of the piece is visual and audio'. The worker inspects the ceramic product at a distance of about 50 cm, then the sanitaryware item is struck to create a sound: if the sound is clear it indicates integrity; if it is muilled there may beone or more breakages in the i ontinuitv ol the ceramic bod\ i.e. cracks, often invisible to the naked eye because covered by glaze or inside the ceramic chamber).

During assessment, sanitaryware is generally divided, with reference to it final installation position, into three zones:

I ligbly visible /one (white zone);

Partially visible zone (blue zone);

Invisible zone (red zone).

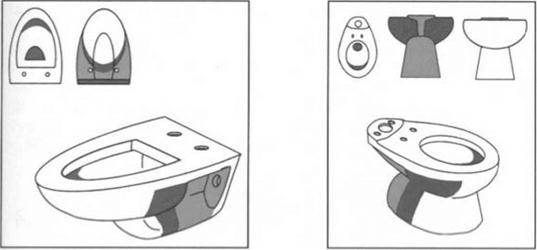

Fig. 'Jus II all-mounted Il V divided Fig. 'J(if) - WC divided into high

into high visibility (white), visibility (white), low

low visibility (blue) and visibility (blue) and

difficult-to-see/tnvi$ikh dif fit ult-to-see/invisible

(red) zones. (red) zones.

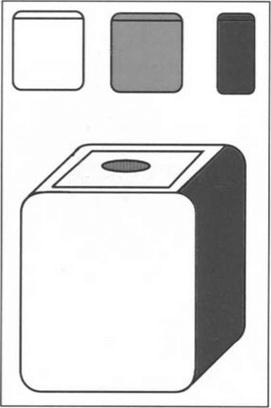

Fig.'JTO- Tink divided into high visibility white'., hru visibility (blue), diffh ult-to-see/invisible (red) zones. The upper figure shows the front (white), rear (red) and side (blue], Vjf the tank.

Fig* 271 - rì>>Wifi'l»iW Olili fifji/i i ijjMi'/j fui/ii'fij. faVTtirit (red) mHtt,

Fig* 271 - rì>>Wifi'l»iW Olili fifji/i i ijjMi'/j fui/ii'fij. faVTtirit (red) mHtt,

Statistical analysis of various ceramic items from several countries have allowed lo draw up taldes illustrating the minimum qualitative requisites for the commercial viability of a product. In the follow ing two tables reference is made to the previous dassilieation of article surface/ones.

Firing

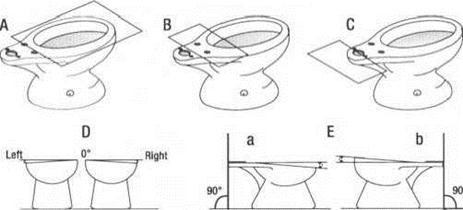

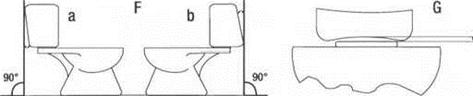

A three-dimensional ce ramie bQdy may suffer from deformation, compromising Éthetics and thus resulting- in rejects, The following tables illustrate, as above, the :atistical research carried out in numerous sanitaryware factories around the world tneerning the maximum allowable deformation values that will pass .sanitaryware

|uality control. The tables are divided in a way that takes the various .sanitarvware ìodels into account- It is evident that w here deformation problems no longer appear

mdomly bui with a certain rc]>eatahilify, the problem must be dealt w ith and resolved

jy making changes on the modelling or production sides.

| POSITION | Maximum acceptable value (mm) | ||

| A | Lack of planarity on upper edge | ||

| B C | Lack of planarity on seat fixing area | ||

| Lack of planarity on tank fixing zone | |||

| D | Twisting | Left | |

| Right | |||

| E | Lack of linearity between vertical surface of wall and that of upper edge of piece | a | |

| b | |||

| F | Misalignment between tank rear and wall | a | |

| b | |||

| G | Misalignment between rank and support surface on WC bowl |

c

Left 0° Right

Chapter 14 DEFECTS

The results achieved hy a sanitarvware produeer depend on numerous factors, many which are not under the producer's full control. For example: market conditions id. therefore, the potential for sales and earnings; the aggressiveness of Competitors id thus their capacity to erode market shares in a free market; bureaucratic and egislative limitations.

Striving lor maximum profit is a question of producers ensuring their own survival, lowever. the component of profit oxer w Inch firms do have control is total production sts and w ithin that scope the question of rejects is fundamental.

The rejection of a sanitaryware item constitutes a net loss, the impact of which ries depending on the point in the production chain at w hich rejection takes place: ejecting an article after it has been fired has a greater impact on the company's irati ng results than rejection at the casting stage.

Kq ti ally important are those delects requiring repair of the ceramic as they torce ie producer to increase the amount of labour invested in each individual piece, thus lising fixed costs.

The goal, then, of a production department must be to minimise the influence defects by identifying and analysing them and then implementing relative lutions.

This chapter provides what is necessarily a short summary of the main, most |uent defects that can lead to rejection or repair of a piece. The follow ing pages scribe the defects that occur at different stages of the production process.

Date: 2015-04-20; view: 1959

| <== previous page | | | next page ==> |

| RE-FIRING | | | CASTING DEFECTS |