CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

agrave;WEG

10. Nipple - A completion component fabricated as a short section of heavy wall tubular with a machined internal surface that provides a seal area and a locking profile. Landing nipples are included in most completions at predetermined intervals to enable the installation of flow-control devices, such as plugs and chokes. Three basic types of landing nipple are commonly used: no-go nipples, selective-landing nipples and ported or safety-valve nipples.

10. Nipple - A completion component fabricated as a short section of heavy wall tubular with a machined internal surface that provides a seal area and a locking profile. Landing nipples are included in most completions at predetermined intervals to enable the installation of flow-control devices, such as plugs and chokes. Three basic types of landing nipple are commonly used: no-go nipples, selective-landing nipples and ported or safety-valve nipples.

11. Sliding slide door- the sliding side door is a pocket in a completion string in offshore oil and gas drilling. this device gives you the opportunity to have communication between tubing and the csg annulus.

12. A sliding sleeve is a standard component for the completion of an oil or gas well. Their main uses are to shut off flow from one or more reservoir zones or to regulate pressure between zones.There are two main categories of sliding sleeves: open/close and choking. Open/close sleeves are shifted between a full open position and a closed position. They are used to shut off flow from a zone for economic reasons or to shut off a zone that is depleting or producing too much water. Choking sleeves are all hydraulically actuated and have a much more complex design than open/close sleeves.

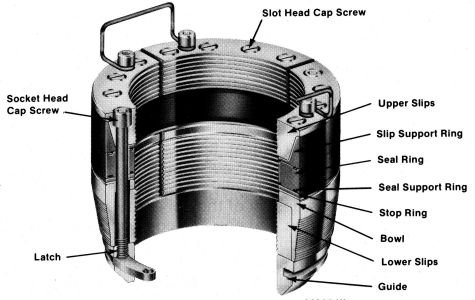

13. casing hanger is that portion of a wellhead assembly which provides support for the casing string when it is lowered into the wellbore. It serves to ensure that the casing is properly located. When the casing string has been run into the wellbore it is hung off, or suspended, by a casing hanger, which rests on a landing shoulder inside the casing spool. Casing hangers must be designed to take the full weight of the casing, and provide a seal between the casing hanger and the spool.

13. casing hanger is that portion of a wellhead assembly which provides support for the casing string when it is lowered into the wellbore. It serves to ensure that the casing is properly located. When the casing string has been run into the wellbore it is hung off, or suspended, by a casing hanger, which rests on a landing shoulder inside the casing spool. Casing hangers must be designed to take the full weight of the casing, and provide a seal between the casing hanger and the spool.

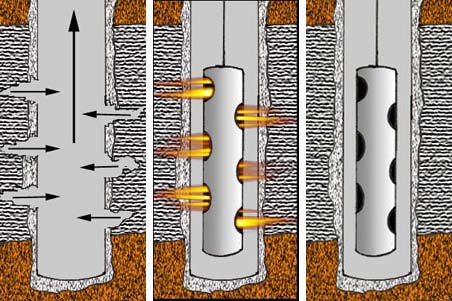

4. perforation - The communication tunnel created from the casing or liner into the reservoir formation, through which oil or gas is produced. The most common method uses jet perforating guns equipped with shaped explosive charges. However, other perforating methods include bullet perforating, abrasive jetting or high-pressure fluid jetting.

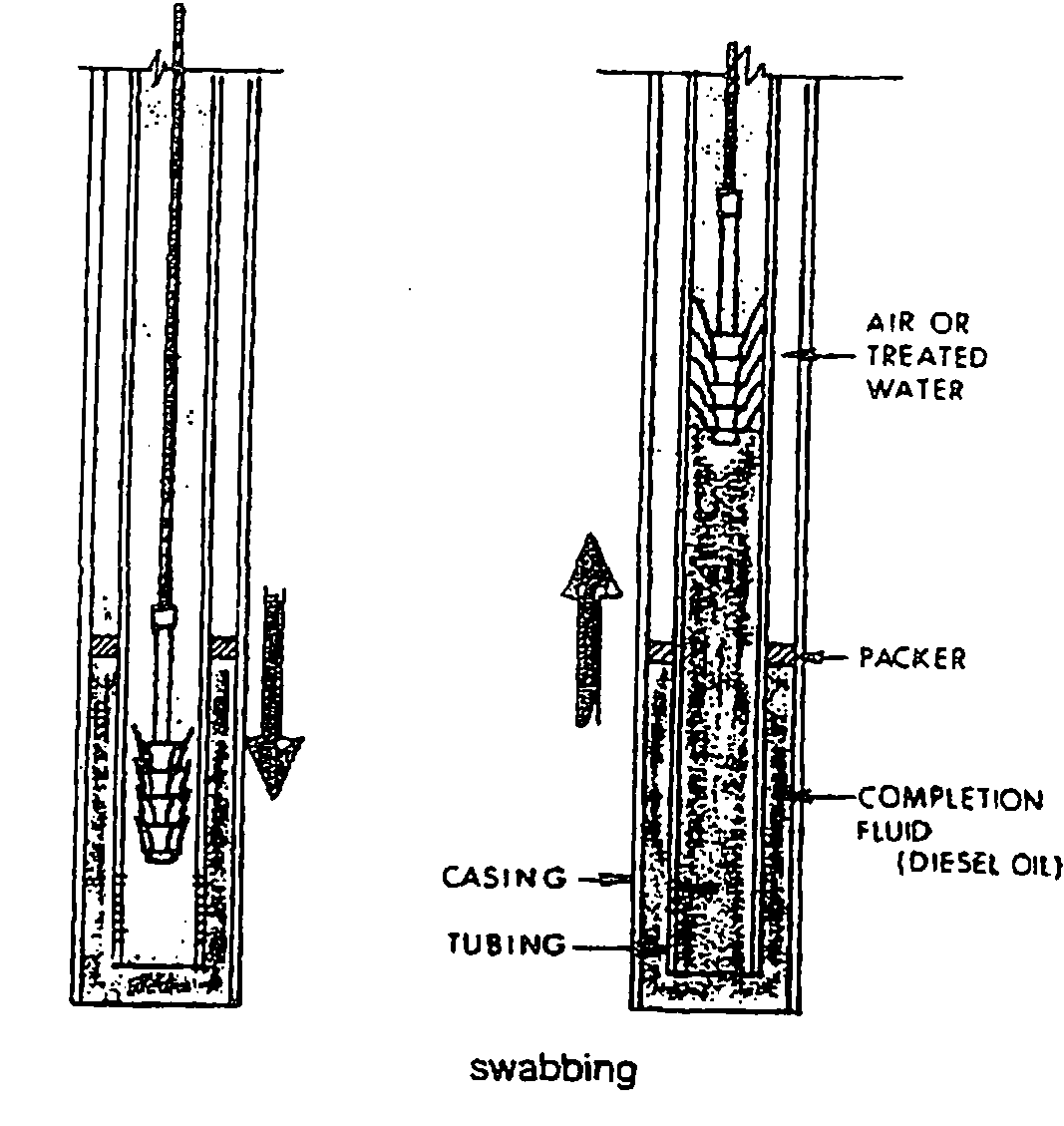

5. swabbing - To unload liquids from the production tubing to initiate flow from the reservoir. A swabbing tool string incorporates a weighted bar and swab cup assembly that are run in the wellbore on heavy wireline. When the assembly is retrieved, the specially shaped swab cups expand to seal against the tubing wall and carry the liquids from the wellbore.

Date: 2015-01-29; view: 5782

| <== previous page | | | next page ==> |

| Well completion | | |