CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Well completion

1. A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. A wellhead serves numerous functions, some of which are:

1. A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. A wellhead serves numerous functions, some of which are:

1. Provide a means of casing suspension

2. Provides a means of tubing suspension. Provides a means of pressure sealing and isolation between casing at surface when many casing strings are used.

3. Provides pressure monitoring and pumping access to annuli between the different casing/tubing strings.

4. Provides a means of attaching a blowout preventer during drilling.

5. Provides a means of attaching a Christmas tree for production operations.

6. Provides a reliable means of well access.

7. Provides a means of attaching a well pump

2. A tubing hanger is a component used in the completion of oil and gas production wells. It is set in the tree or the wellhead and suspends the production tubing and/or casing. Sometimes it provides porting to allow the communication of hydraulic, electric and other downhole functions, as well as chemical injection. It also serves to seal-in the annulus and production areas.

2. A tubing hanger is a component used in the completion of oil and gas production wells. It is set in the tree or the wellhead and suspends the production tubing and/or casing. Sometimes it provides porting to allow the communication of hydraulic, electric and other downhole functions, as well as chemical injection. It also serves to seal-in the annulus and production areas.

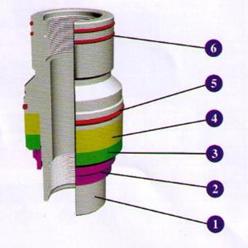

| Tubing Hanger Body | |

| Nut | |

| Gasket | |

| Seal Ring | |

| O-ring | |

| O-ring |

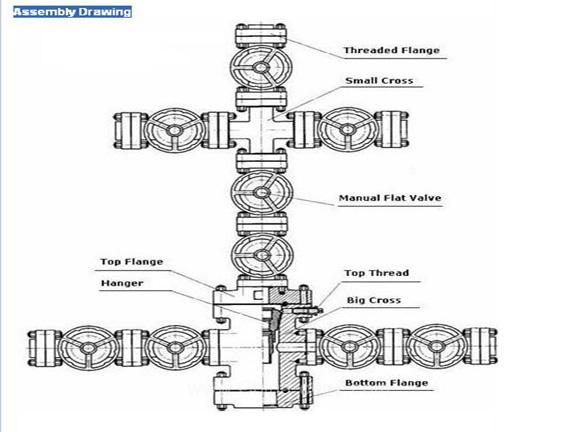

3. X-tree - the set of valves, spools and fittings connected to the top of a well to direct and control the flow of formation fluids from the well. An assembly of valves, spools, pressure gauges and chokes fitted to the wellhead of a completed well to control production. Christmas trees are available in a wide range of sizes and configurations, such as low- or high-pressure capacity and single- or multiple-completion capacity.

3. X-tree - the set of valves, spools and fittings connected to the top of a well to direct and control the flow of formation fluids from the well. An assembly of valves, spools, pressure gauges and chokes fitted to the wellhead of a completed well to control production. Christmas trees are available in a wide range of sizes and configurations, such as low- or high-pressure capacity and single- or multiple-completion capacity.

4. A liner hanger is a device used in oil fields to hang liners within an oil well. So that oil can be pumped out of the well, a liner is used to create a vacuum. Liners can be installed mechanically or hydraulically, depending on the well. Setting a hanger is a crucial part of the process of "completion" which is the preparation of an oil well for drilling. à

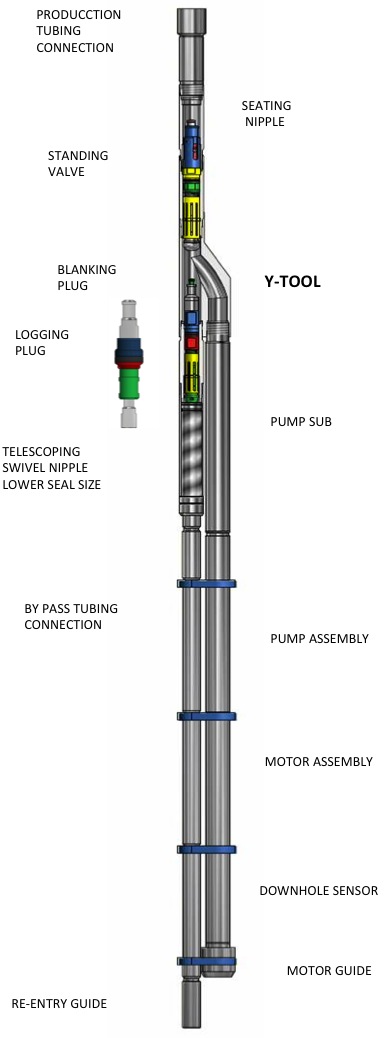

5. The Y-tool is a solution to enable intervention or logging with wireline or coiled tubing below an ESP. it is installed on a production tubing and provides two separate conduits. One is concentric with a production tubing and enables access to the reservoir below the ESP. second is offset and used to support ESP system.

6. The packer isolates the annulus between the tubing and the inner casing and the foot of the well. This is to stop reservoir fluids from flowing up the full length of the casing and damaging it. It is generally placed close to the foot of the tubing, shortly above the production zone.

7. A subsurface safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst case scenario surface disaster. It is almost always installed as a vital component on the completion.

7. A subsurface safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst case scenario surface disaster. It is almost always installed as a vital component on the completion.

ßSSV

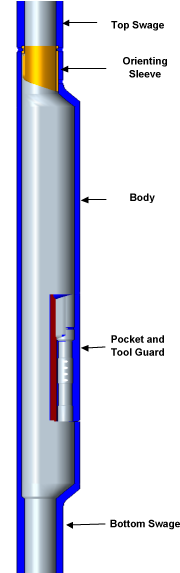

8. Side pocket mandrel- This is a welded/machined product which contains a "side pocket" alongside the main tubular conduit. The side pocket, typically 1" or 1½" diameter is designed to contain gas

lift valve, which allows hydrocarbon gas from the A annulus to be injected into the flow stream. -->

lift valve, which allows hydrocarbon gas from the A annulus to be injected into the flow stream. -->

Wireline entry guide. - This component is often installed at the end of the tubing, or "the shoe". It is intended to make pulling out wireline tools easier by offering a guiding surface for the toolstring to re-enter the tubing without getting caught on the side of the shoe

Date: 2015-01-29; view: 9436

| <== previous page | | | next page ==> |

| Welcome to the World of Nanotechnology | | | agrave;WEG |