CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Man must build

(Implementation of practical class plan):

At the beginning of the class a teacher calls the register and designates a student on duty, names the topic and purpose of the class, finds out unclear questions, which appeared during independent work of students.

Then the teacher analyzes subject questions, tasks of students’ research work and methods of practicing skills in accordance with the methodologic instruction, by means of actively questioning all students of the group.

The teacher is guided by the extent of knowledge obtained by the students during their independently studying the material in the textbooks, lecture notes and methodologic instructions, as well as preparing students’ research work in the albums for independent work.

Besides, the teacher can choose to check the hometask in oral or written form, as well as in mixed and oral-and-written form. The teacher can use situational tasks and test questions in addition to routine subject questions.

Having controlled the students’ knowledge for the class, the teacher demonstrates to the students methods of preparation and obtaining of a print thermoplastic impression material.

After the demonstration the students start to independently train practical skills on each other under supervision of a senior laboratory assistant or the teacher.

At the end of the class the teacher gives marks for oral answer or written work, for independent students’ work, signs the protocol of the laboratory work, as well as names the next topic and questions for study.

Summary

Processing the denture

After the trial dentures (Acrylic base, wax and teeth) have been waxed, they are prepared for denture processing to substitute the acrylic record base and the wax with a hot cure denture base attached to the teeth. This is done in the following steps:

1) Flasking.

2) Wax elimination.

3) Mixing.

4) Packing.

5) Curing.

6) De-flasking.

7) Shaping and Polishing.

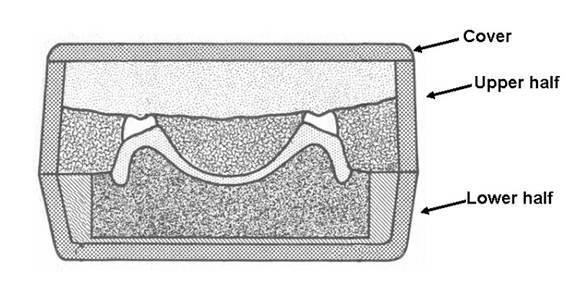

Flask: Is a metal case or tube used in investing procedures.

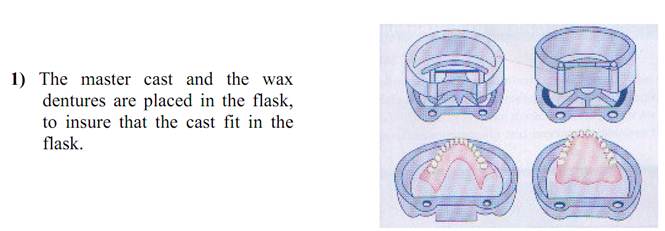

Flasking: The process of investing the cast and a waxed denture in a flask to make a sectional mould used to form the acrylic resin denture base.

The flask is made of 3 major parts, (1) lower half (which contains the cast), (2) upper half and (3) the cover or lid. The lower half may have a round plate, covering a round hole in the base of the lower half.

1) Flasking:

Molding or flasking Techniques:

1- Compression technique:

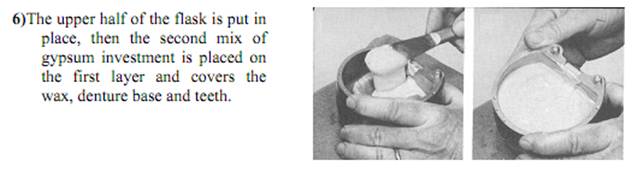

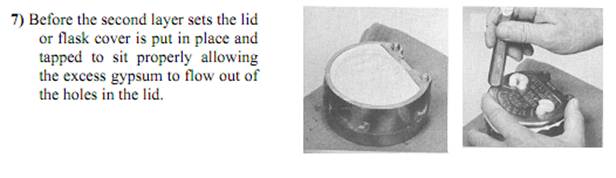

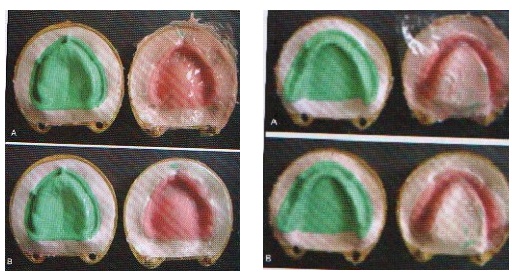

The stone cast with the record denture base, wax and teeth are secured to the lower half of the flask with gypsum investment material (plaster or stone). Then the upper half of the flask is put in place and gypsum is poured to the occlusal surfaces of the teeth. Finally the top portion of the flask is poured with investment and the lid is placed on the flask.

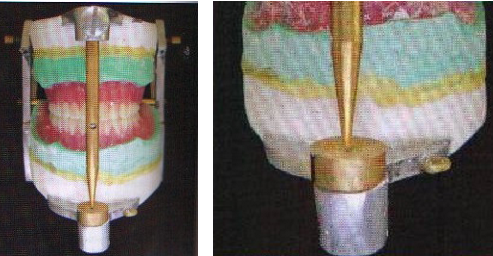

2- Injection molding technique:

It is a complicated procedure requiring special flask and equipment. In this technique the wax pattern is sprued and the material is injected into the mold. This process allows injection of further material during polymerization to compensate for the polymerization shrinkage.

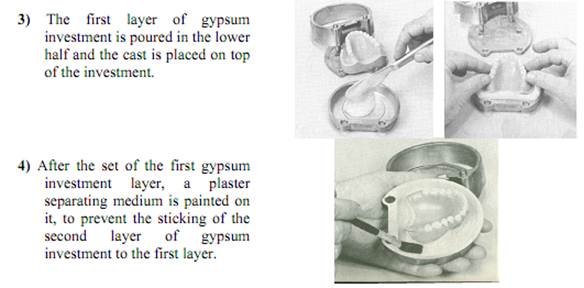

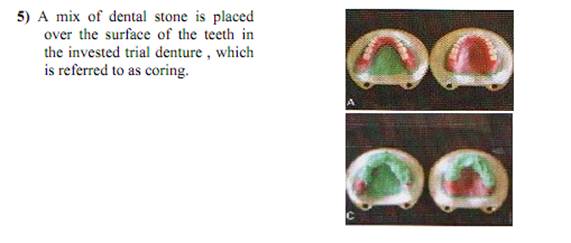

The procedure of flasking a denture in compression technique is as follows:

3- Mixing:

Acrylic resin dough is made by mixing the powder (polymer) and liquid (monomer) to form 'dough' which is packed into a gypsum mold for curing. The ratio of powder to liquid is important since it controls the workability of the mix as well as the dimensional changes on setting.

The mixing should be done in a clean jar which should be covered to prevent evaporation of the monomer.

4- Packing:

It should be done when the mixture reaches dough stage, as the dough is rolled into a rod-like form and placed in the upper half of the flask then a polyethelen (nylon sheet) is placed over the dough in the upper half and then the two halves of the flask are closed until they are almost in approximation, this is done to spread the dough evenly throughout the mold. Then the two halves of the flask are separated, the excess material at the borders of the denture is removed by a wax knife, and additional resin is added at any places that are deficient. At least two trial closures are done and before the final closure a thin layer separating medium is applied on the cast and the polyethelen sheet is removed and then the two halves of the flask are closed under pressure by bench press of about 100 Kg/cm2. Then the flask is put in a spring clamp and the clamp is closed tightly.

5- Curing:

It is polymerization of the hot cure acrylic to produce the final denture. The material is cured by heating in a water bath; pressure is applied during curing for the following reasons:

1- To decrease the effect of thermal expansion.

2- To decrease the polymerization shrinkage.

3- To increase the evaporation of monomer thus decreases porosity.

Types of curing cycles for heat cure acrylic:

1- Short curing cycle.

2- Long curing cycle.

1- Short curing cycle:

The denture is placed in water at room temperature and the curing temperature is programmed to 74 oC for one and half hour followed by 100oC for one hour.

2- Long curing cycle:

The curing temperature is programmed to 100 oC for 8 hours.

Polymerization can occur at any temperature but it is very slow at temperature below 70oC, the best curing cycle is the long curing cycle because most of the conversion of monomer to polymer occurs during the period at 70oC and during this time the dough itself may approach 100oC because the polymerization reaction exothermic. The monomer boils at 100.3oC so the dough must be kept below this temperature to avoid boiling of the monomer; on the other hand rapid curing cycle usually results in some gaseous porosity.

6- Deflasking:

Deflasking is the process of removal of the processed denture from the flask and investment mold. Before deflasking of the processed denture begins the flask is left to cool to room temperature. If not, increased distortion of the acrylic may occur.

Laboratory remount

The denture should be remounted on the articulator as dictated by the indices with sticky wax. The incisal pin discrepancy should be noted. If the discrepancy is less than 2mm, it is acceptable. If the discrepancy is between 2-5 mm, occlusal correction can be accomplished.

If the discrepancy is more than 5mm, the entire treatment should by repeated.

7- Shaping and Polishing:

In this step any excess acrylic is removed from the processed denture by the use of stone wheel burs, stone burs, and steel burs. Care must be taken not to heat the denture during grinding, because this may cause distortion of the denture base. Finally, the denture should be smooth and clean, as no plaster and no deep scratches should remain after the preparation for polishing.

In polishing a rag wheel with pumice is used for smoothing the denture. Then a final high polish is given to the denture with a rag wheel and polishing material (Rouge).

Special-purpose Training Tests for study the topic level testing

1. Patient with complete loss of teeth on the upper jaw is made a complete removable denture. After plastic polymerization the flask is removed from the hot and is rapidly cooled under running cold water. What do you think will happen in a plastic prosthesis basis in this case.

A. -pressure porosity is formed

B. -gas porosity is formed

C. -granular porosity is formed,

D. -the color of plastic changes

E. +microcracks occur

2. The patient, 57, is made a removable plate prosthesis for the upper jaw. On clinical and laboratory stages of its manufacture dental wax is used. Which group is the material related?

A. -insulation

B. -forming

C. -polishing

D. + modeling

E. -impression

3. A patient, 73, addressed to the clinic with complaints of poor fixation of complete removable dentures, manufactured 10 years ago. On check-up: reducing the lower third of the face, a large uniform atrophy of the alveolar processes. Oclussion surface of artificial teeth is almost completely erased. After how many years of use removable dentures patient should change them.

A. -7-10 years

B. -7-8 years

C. -1-2 years

D. -9-10 years

E. +3-4 years

4.Patient,70, complaines of a lack of fixation of complete removable dentures on the upper jaw. Objectively: the edge of the prosthesis in the frenulum of the upper jaw is shortened, the locking valve is broken. What should be done to improve the fixation of the prosthesis.

A. +Denture reproduction

B. -Denture correction

C. -Expansion of denture basis edges

D. Extansion of denture basis edges

E. -Volumetric modeling of denture basis

5. The patient, 70, is made complete removable dentures for the upper and lower jaws. Formulation of artificial teeth produced by the method of Vasiliev. What kind of teeth in the upper denture inappropriately must not touch the glass.

A. -Canines and first molars,

B. -central incisors and first molars,

C. first and second premolars

D. + lateral incisors and second molars,

E. -second premolars and first molars

6. Patient,47, is made complete removable dentures for the upper and lower jaws. The review stage of their construction shows protrusion of the upper lip. What stage was a mistake on?

A. -Determining the height of the lower third of the face

B. + The formation of the vestibular surface of the bite roller,

C. -Forming the occlusal plane

D. -Determination of the height of the upper bite roller

E. -Central occlusion fixation

7. A patient,73, addressed to the prosthodontics clinic at the basis of fracture of complete removable dentures on the upper jaw. The prosthesis was made a year ago, of satisfactory quality. What plastics must be used to fix the prosthesis in this patient.

A. -Carboplast

B. +Protacril-Ì

C. -Bacrel

D. -Etacril

E. -Ftorax

8. The patient,70, with complete loss of teeth on the upper and lower jaws, is made complete removable dentures. Teeth setting will be conducted according to individual occlusal surfaces (the method of Napadov and Sapozhnikov). What material should rollers be made from for individual occlusal surfaces?.

A. -Adhesive wax

B. -Plastic

C. -Lavax

D. +waxabrasiv

E. -Stens

Man must build

Read the text

Man Must Build

Early builders were at first concerned almost entirely with constructing shelters against rain, cold, wild beasts, and human foes. Later, as their civilizations developed, they built temples, council chambers1, bazaars, and palaces. They took a special delight in erecting pyramids, towers, obelisks, coliseums, and the like.

The story of modern structures is the story of the break from the materials of the past. Great and noble structures were built in brick, timber, and particularly in stone, but now steel and concrete have largely replaced them. With these newer materials we can build to greater heights, span wider gaps, and carry heavier loadings than ever before. In many countries today, mountainous masses of steel and concrete are reaching to the skies on a scale undreamed of in earlier times. Engineers have been able to do this because the rise of the science of structures and the advent of steel and concrete have enabled them to conceive and build their buildings and their structures as frameworks.

Before this, the walls of buildings were "bearing" walls: they carried the dead weight and the live load of the structure. The modern large building, however, is essentially a framework or skeleton of steel or concrete that supports the roof and floors. The outside walls are enclosing or "curtain" walls, and often their weight at each floor is also taken by the framework. So the "sidewalk superintendent,'' gaping curiously at the busy scene on a building site, may see the walls rising simultaneously from the ground and midway between roof and ground. Since the walls do not earn' the structure, they are sometimes made of glass or plastic.

When the lift-slab method was first devised, some people described it as a way of constructing a building from the top downward. The description, however fanciful, draws attention to the novelty of the system. The method does, nevertheless, give an excellent illustration of the framework principle employed in most modern buildings.

One begins by constructing the various floors and the roof on top of one another, and around the columns, at ground level. These are then lifted by powerful hydraulic jacks to their correct positions in the structure, and permanently connected to the columns. In the case of a nine-storey building, the columns may be erected in three stages, and the tops of each stage temporarily braced together by the ascending roof. As the roof and higher floors move upward, they leave behind lower floors which, secured to the columns, serve to brace them permanently together. In this type of structure, therefore, the floors and the roof serve the added purpose of forming part .of the framework. When roof and floors are all finally in place and connected to the columns, the protective walls can be built up from ground level.

In large buildings, the civil engineer's main task is the design of frameworks and foundations.

Left, model by Mies van der Rohe for a glass skyscraper, 1920. Right, Tokyo hotel designed by Frank Lloyd Wright; it rents on a concrete raft (diagram).

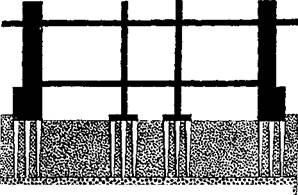

Where a building is supported by its walls, the weight is spread out over a large area. This gives relatively low pressures on the ground and makes foundation work easy. But in a modern building framework, the load is carried by a small number of columns, which leads to highly concentrated ground pressure. Hence the foundations must be strong, particularly if the ground is weak.

If the ground is reasonably firm, it is often enough to place the columns on spread footings. These are blocks of concrete of such area as to spread the load to within the carrying strength of the ground. On soft ground, a building is sometimes put on a concrete raft, which is a footing covering the whole ground plan area. A building on its raft is virtually floating on the ground beneath. A method often used is to drive a number of piles under each column foundation. The piles are made long enough to rest on the hard ground below the soft surface. The building is then literally on stilts. Another method is to carry the columns on fairly large diameter cylinders sunk deeply into the ground.

Below, the Empire State Building lowers above :he skyscrapers of New York.

II. Answer the following questions.

1) What factors have led to the revolution in the "history of modern structures"?

2) Why is the «framework principle» used widely in modern constructions?

3) How does the "lift- slab" method work?

4) Why is it necessary for civil engineers to pay special attention to the design of frameworks and foundations?

5) What types of foundations are mentioned in the text?

III. Describe the types of foundation works given in the text. Determine what conditions must be considered to choose the right type of foundation works.

IV. Are these statements true or false?

Correct the wrong statements.

1. The outside walls of new buildings are "bearing walls".

2. The weight of the outside walls is taken by the foundations.

3. "The lift -slab" method consists in the construction of the frame and floors on the top level.

4. The structure of the ground under the construction should be thoroughly examined.

5. It is enough to place the columns on spread footings if the ground is firm.

V. Complete the sentences using an appropriate link.

| 1. Engineers have been able to achieve new results 2. The walls of the buildings were bearing walls 3. We can build to greater heights, span wider gaps 4. In a mass construction the building is supported by its walls 5. In a modern building the foundations must be strong | due to therefore since thus because | a) The rise of the science of structure and the advent of steel and concrete have enabled them to build their structures as frameworks. b) The weight is spread out over a large area. c) The load is carried by a small number of columns. d) Advanced techniques in building and progressive building materials e) They carried the dead weight and the live load of the structure |

VI. Match the word from column A to its synonym in column B.

A B

1. to substitute a) to place

2. to carry the load b) to replace

3. to invent c) to support

4. to settle d) to devise

5. to uphold e) to bear

Fill in the gaps with the words from column A.

1. New materials _______ the old ones and with these materials we can build to greater heights

and ______ the greater_______.

2. When the lift-slab method was first _______, some people described it as a way of constructing a building from the top downward.

3. The protective walls can be built up from ground level, when roof and floors, are finally

4. As a mass construction is _____________by its walls, the weight is spread out over a large

area.

VII. Translate into English the following word combinations. Use them in the statements of your own.

VIII. A) Fill in the gaps with appropriate words.

| ground, foundations, skyscrapers, support, steel frames, hung, occurs, strong vibration, level of the tunnels, underlying |

A study of some of New York's______________would convince you that in modern buildings the walls no longer act as ______________. To overcome ______________ from subway trains passing near the ______________, the ___________ are taken down below the______________and anchored in the solid rock____________ Manhattan. The walls are______________on the frame, but they do not touch the______________where the vibration______________. The Waldport Astoria Hotel is a good example of it.

B) Put the word given in brackets into the necessary word form.

The Pirelli skyscraper in Milan is of most modern concrete design. A tall shaft, 32 storage (height) is cigar (shape). Four mass columns (extension) across the structure and present the (solve) to the difficult wind (resist) problems. Special account was taken of the severe (torsion) strains to which such a delicately proportioned building is subject. In order to check the (calculate) a 1/15th scale model was tested. And now the finished structure stands, giving (express) to the words of a (fame) French architect who spoke of the (accumulate) of very beautiful things in which economic law reigns (supremacy) and (exact) is joined to (imagine). That is beauty.

IX. Read the texts again and think of the main problems of these constructions and the engineering solutions to these problems.

X. Study some properties of steel and concrete.

| steel concrete | has the property of | high tensile strength high compressive strength |

| this means | it can resist | high tensile forces high compressive forces |

XI. There are 3 types of building constructions read the decide which paragraph discusses.

a) a mass construction

b) a frame construction

c) a planar construction

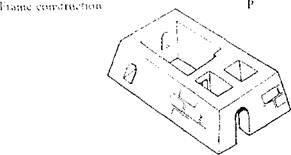

Building materials are used in two basic ways. In the first way they are used to support the loads on a building and in the second way they are used to divide the space in a building. Building components are made from building materials and the form of a component is related to the way in which it is used. We can see how this works by considering three different types îf construction:

1. In one kind of construction, blocks of materials such as brick, stone, or concrete are put together to form solid walls. These materials are heavy, however, they can support the structural loads because they have the property of high compressive strength. Walls made up of blocks both support the building and divide the space in the building.

lanar construction

Mass construction

2. In another type of construction, sheet materials are used to form walls which act as both space-dividers and structural support. Timber, concrete and some plastics can be made into large rigid sheets and fixed together to form a building. These buildings are lighter and faster to construct than buildings made up of blocks.

3. Rod materials, on the other hand, can be used for structural support but not for dividing spaces. Timber, steel and concrete can be formed into rods and used as columns. Rod materials with high tensile and compressive strength can be fixed together to form framed structures. The spaces between the rods can be filled with light sheet materials which act as space dividers but do not support structural loads.

XII. Say whether these statements are true or false. Correct the false statements.

1. Rod materials can be used for both dividing space and supporting the building.

2. Concrete is used as a block material, a sheet material and a rod material.

3. Steel is used for frame constructions because it has a property of high tensile strength and low compressive strength.

4. The sheet materials, which act as space dividers in a frame building are light because they do not support structural loads.

5. Mass construction buildings are light whereas planar constructions are heavy.

Date: 2014-12-22; view: 4492

| <== previous page | | | next page ==> |

| ORGANIZATIONAL STRUCTURE OF THE practical CLASSES | | | PERFECT TENSES PASSIVE |