CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Flushing out of the borehole drilling fluids, which were introduced during the drilling process.

Drillers who have specialized their drilling in a specific formation area become expert at knowing the most effective and efficient (i.e. the best use of time and equipment) to develop the wells in their area. Some drillers have little experience with screen well development; other drillers have extensive experience in this area.

The material to follow is broad in scope in that it surveys well development practices used in the United States in certain formation areas. All the processes described have proven their worth in some formations with some well types.

THE BASIS OF ALL WELL DEVELOPMENT METHODS

IS TO CARRY OUT ACTIVITIES THAT WILL MAKE IT EASIER

FOR WATER TO REACH THE PUMP SUCTION

FOR WATER TO REACH THE PUMP SUCTION

COMPARING

SEVERAL

METHODS

OF WELL

DEVELOPMENT

Source: Groundwater and Wells, 2nd edition

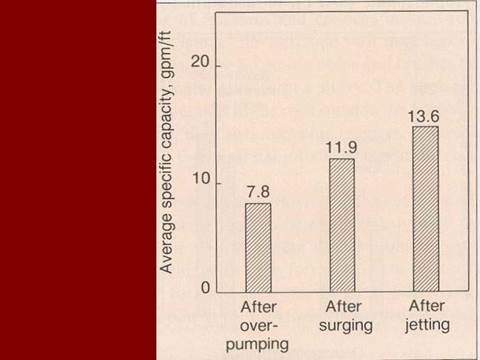

“… eventual specific capacity of a well depends to a great extent on what development method is used.”

The graph above shows clearly the impact on specific capacity when overpumping was followed by surging, and then surging was followed by jetting. Specific capacity of the wells involved in this controlled test were improved 74% when a 3 step development approach was employed. The results shown above are for screen wells rotary drilled with bentonite fluid additives.

The general conclusion to be drawn is that well development is best done with a combination of methods approach, whichever methods are chosen.

Whatever the method used, the ultimate purpose of “developing the well” is the same. Well development is carried out to maximize well yield. All new wells should be developed before being put into production to achieve sand free flows and maximum yield.

There are two main objectives to be achieved through well development. To the extent that either or both objectives are achieved better well yield will be the result.

The first objective is to repair damage done to the formation immediately surrounding the borehole by the physical operation of drilling. It is in this area that cable tool drillers and rotary drillers often discuss the impact of their chosen method on the formation and ultimately on well yield.

Repairing the damage to the formation involves:

Removing any “clay smear” or “mud cake” covering the aquifer surface.

Flushing out of the borehole drilling fluids, which were introduced during the drilling process.

Date: 2016-03-03; view: 953