CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

WORKING CYCLE OF THE FOUR-STROKE

CARBURETTOR ENGINE.

As distinct from the diesel engine, in the carburetor engine, fuel and air enter the cylinder in the form of an air-fuel mixture prepared by the carburetor.

Each of the strokes in the working cycle of the four-stroke carburetor engine, as in the diesel engine, is characterized by the position of the valves and the direction of the piston travel. The cycle of operations of the four-stroke carburetor engine occurs as follows.

Intake

The piston moves downwards. The intake valve is open. As a result of a vacuum produced by the downward movement of the piston, the air-fuel mixture prepared by the carburetor enters the cylinder through the open intake port and, intermingling with the unscavenged exhaust gases, forms the combustible charge.

Compression

The piston moves upwards. Both the intake and the exhaust valves are closed. The volume above the piston diminishes and the combustible charge is compressed, which facilitates the evaporation of gasoline and mixing of gasoline vapor with air. By the end of the compression stroke, the pressure in the cylinder reaches 1 to 1.2 MPa and the temperature, 350 to 400°C.

POWER – burning of fuel and expansion of combustion gases

Both valves are closed. At the end of the compression stroke, the combustible charge is ignited by a spark. The piston moves down from TDC to BDC under the pressure of expanding combustion gases. The pressure of the gases reaches 2.5 to 4 MPa and their temperature, 2000°C.

Exhaust

The piston moves upwards. The exhaust valve is open. The spent exhaust gases leave the cylinder through the exhaust port.

Diesel engines are more economical than their carburetor counterparts. As a result of their higher compression ratio, the diesel engines burn 25% less fuel (per unit work done).

Diesel engines operate on heavy fuels that present less fire hazard in handling.

The diesels, however, feature some disadvantages:

they are more bulky, for the high pressure of combustion gases in the cylinder requires stronger engine components; hey are more difficult to start, especially in cold weather.

2.3. WORKING CYCLE OF THE TWO-STROKE CARBURETTOR ENGINE (Fig. 4).

The two-stroke engine has no valves. The intake of the air-fuel mixture and the exhaust of the burnt gases are affected through ports cut in the cylinder wall, which are timely opened and closed by the moving piston.

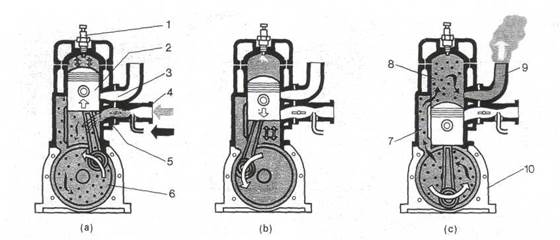

As piston 2 (Fig. 4a) moves upwards, it closes exhaust ports 3 in the cylinder wall, as a result of which final compression of the combustible charge transferred earlier in the stroke from sealed crank chamber 6 to the cylinder takes place above the advancing piston. At the same time, a fresh charge of fuel and air is taken from carburetor 4 into crank chamber 6 through intake ports 5, as a result of the depression produced below the piston as it retards towards the end of its stroke.

As the piston nears TDC, a spark jumps across the points of spark plug 1 (Fig. 4b) and the combustible charge in the cylinder is ignited. This marks the end of the first (intake) and compression stroke.

|

Fig.4. Illustrating the operation of a two-stroke engine

(a) the first (intake and compression) stroke;

(b) the end of the first stroke and the beginning of the second (power and exhaust) stroke;

(c) the end of the second stroke;

1 - spark plug;

2 - piston;

3 - exhaust port;

4 - carburettor;

5 - intake port;

6 - crank chamber;

7 -scavenge (transfer) passage (port);

8 - cylinder;

9 - exhaust pipe;

10 - crankcase

Under the pressure of the expanding combustion gases the piston moves downwards on its power stroke which continues until the exhaust ports are opened and the evacuation of the exhaust gases from the cylinder commences. As the piston moves downwards, the previously induced charge trapped in the crank chamber beneath the advancing piston is partially compressed. At the end of the second (power and exhaust) stroke, the piston opens scavenge (transfer) passage (port) 7 and the partially compressed charge of air-fuel mixture previously trapped in the crank chamber enters the cylinder, expelling the exhaust gases out of it (Fig. 4c). The cylinder is simultaneously scavenged and filled with a fresh air-fuel mixture, the latter being partially lost together with the exhaust gases leaving the cylinder. Thus, the working cycle of the engine is completed in two strokes of the piston. Engines with the above-described cycle of operations are referred to as scavenged engines. These engines are simpler, both in design and operation, than four-stroke engines. They run more smoothly, because the power stroke in them occurs at each revolution of the crankshaft. Two-stroke engines, however, are less economical than four-stroke ones, up to 30% of air-fuel mixture being lost in scavenging. For this reason, such engines in tractors are used only under short-term service conditions for starting the main diesel engine.

Date: 2015-12-24; view: 2171

| <== previous page | | | next page ==> |

| WORKING CYCLE OF THE FOUR-STROKE DIESEL ENGINE. | | | Operation of Multicylinder Engines |