CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Introduction to Polymer Science and Technology Introduction

Plastics grow on trees! Biodegradable plastics (suitable for the production of bottles and similar containers) have been grown in plants such as the mushroom plant and sugar beet by employing genetic engineering.

Monsanto are growing biodegradable plastics plants by genetic engineering.

1.2.4 Design for recyclability

Manufacturing economics and concerns about environmental pollution have combined to put pressure on the designer to re-think the approach to product design, and to consider the entire life-cycle of the product. The technical challenges associated with the recovery and recycling of the major plastic components are being addressed by the plastics industry, original equipment manufacturers (OEMs) and an emerging appliance recycling industry. A widespread recovery of valuable plastics from discarded products will provide significant life cycle benefits.

The increased use of plastics in industries, e.g., automotive, is due to advantages such as reductions in weight, cost savings, greater manufacturing flexibility and shortened lead times. One drawback, particularly in the face of stringent EU legislation, is the lack of effective separating and recycling technology, which becomes a hindrance to the realisation of the full potential of plastics.

1.2.5 Solve problems

The urgencies of war, for example, have been the driving force for many of the most remarkable developments in materials, often to provide a solution to problems which previously simply did not exist, or at least were not perceived to exist.

Introduction to Polymer Science and Technology

Introduction

1.2.6 Challenge and replace traditional materials

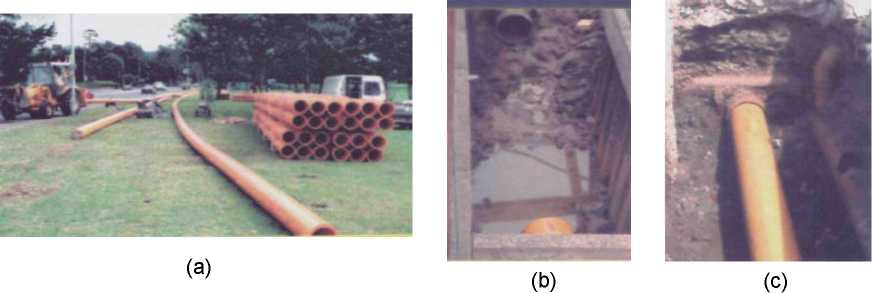

Plastic mouldings have demonstrated their worth in a number of industries. The major benefits, as alternatives to metals, are parts consolidation (i.e., fewer materials and components in one part), lower weight, improved strength and stiffness-to-weight ratios, corrosion resistance, and reduced cost of parts. Figure 1.2 shows scenes from the Phoenix pipe-laying operation along the Shore Road, near the University of Ulster. Phoenix purchased the old Belfast gas system and used it as a conduit for inserting new pipeline. This minimised disruption and maximised productivity by limiting trench digging.

Figure 1.2High density polyethylene (HDPE) replaces iron as gas-transmission pipes: (b) shows both old and new pipes and (c) the insertion of

HDPE pipe into the old iron pipe

Replacement of metals with polymer-based materials occurs regularly in nearly all engineering sectors and is regularly forecast by practitioners: Humphreys (1997, p50) in his contribution to UK-Japan Symposium on Science and Society states, "Seventy per cent of the weight of a suspension bridge is in the steel cables. If you make the bridge longer and longer, it can no longer hold up its own suspension cables. The maximum length or span of a conventional suspension bridge is 5,000 metres. If you replace the steel ropes with carbon fibre ropes, however, then one can calculate that the maximum span goes up by a factor of three. In principle, you could have a suspension bridge which is 15, 000 metres long." This notion was also expressed by Ramsden (2009) in his analysis of the suspension bridge over the Strait of Messina, connecting the Italian mainland to the island of Sicily. Steel cable is to be used over a 3,300 m span. However he states that longer bridges may have to consider the use of carbon and glass fibre composites.

Humphreys (1997, p48) further advocates the replacement of steel rope with carbon-fibre rope for tethering floating oil/ gas rigs to the sea bed: he states that all our North Sea floating rigs have got huge buoyancy bags to keep them afloat. "At a certain depth of water, beyond 1500 m, it becomes impractical (with steel rope) to add more buoyancy bags. However, if steel rope is replaced by carbon-fibre rope, then you can go down to 3000 m, making it possible to extract oil and gas in much deeper waters. This fact, it is known, will transform the world energy scene. ...there are huge reserves of oil and gas which are now, in principle, accessible which were not accessible previously. Its all due to the production of lighter tethers, five times lighter than steel."

These applications foreseen a decade ago for carbon-fibre or a similar synthetic fibre rope have yet to be fulfilled but it should only be a matter of time. Some high-performance engineering ropes based on polyester, nylon and ultra-high-molecular-weight polyethylene fibres are produced by Bridon Ropes (http://www.bridon.com/index.php).

Date: 2015-12-11; view: 1053

| <== previous page | | | next page ==> |

| Introduction to Polymer Science and Technology Introduction | | | Introduction to Polymer Science and Technology Introduction |