CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Hydraulic fracturation

An impervious (or impermeable) formation impeding fluid drainage may allow the fluid to increase in pressure up to the lithostatic pressure and even more. The formation may break if its resistance is overcome.

Among the possible causes of fluid-pressure increase in rocks, dehydration or melting reactions are the more common. The structure of the impregnated medium containing the fluid may disintegrate by fracturation and, if the percentage of fluid is important (> 40 % for example) the medium may behave as a suspension of a solid in a liquid, hence loose any mechanical resistance (its viscosity approaching that of a liquid) : the material is said as « undercompacted ».

Such a liquefied material, may serve as a décollement level able to transport thrust nappes over large distances.

Hydraulic fracturing (hydrofrac) is common in the oil industry for reservoir stimulation in order to maximize oil or gaz recovery, and in geothermal power-plants to increase the exchange surface of rocks.

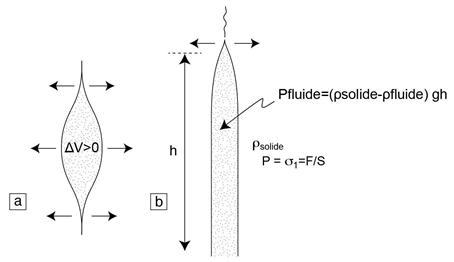

Figure. Principle of hydraulic fracturation through fluid overpressure. a : by volume increase of the fluid due to a dehydration or melting reaction : rock vol. before reaction < vol. rock + vol. fluid after reaction. b : at the upper tip of a fluid colomn in a rocks (rsolid > rfluid).

IX. STATES OF STRESS AND IN-SITU STRESS MEASUREMENTS

1. State of stress

In ductile materials the differential stress is rather low (in magnitude) since they cannot carry high pressures … they readily deform. However (paléo-)stress measurement methods have been developed by metallurgists, mainly by using the recrystallized grain size (since the stress magnitude is directly connected to production of the dislocations, itself directly connected to the formation of dislocation walls and ultimately of new grain boundaries …). In ductile materials geologists are mostly interested by the orientation of the far stress field, itself revealed by the preferred orientation fabrics of plastically deformed minerals (quartz, olivine) : dextral or sinistral senses of shear, or the presence or not of a coaxial component … give a clear indication on the orientation of the maximum and minimum principal stress vectors.

Figure. Markers of non-coaxial deformation. a and b : Pressure shadow and rotated inclusions in garnets. Orientation of the maximum principal stress vector is NW-SE.

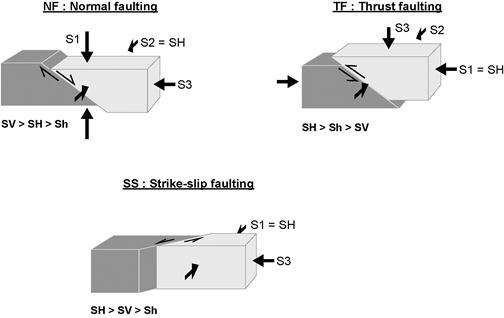

Note that the states of stress (through time) in a region can be evaluated directly by reading a geological map, by looking to the shear zones and the shear sense indicators for the high-T events, and to the normal/thrust or strike-slip faults for the low-T events (Figure) …

Figure. Orientation of the principal stress components in the 3 principal fracture systems

In the « real world », the need of determining the magnitude and orientation of the stress « vectors » comes mostly from the oil industry, the mining the civil ingeneering companies ? this aspect is now examined in more details

Date: 2014-12-28; view: 4914

| <== previous page | | | next page ==> |

| VIII. RUPTURE IN PRESENCE OF FLUIDS | | | Hydrofracturation |