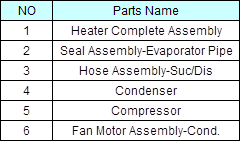

CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

REFRIGERANT CIRCUITAir conditioning System

Contents

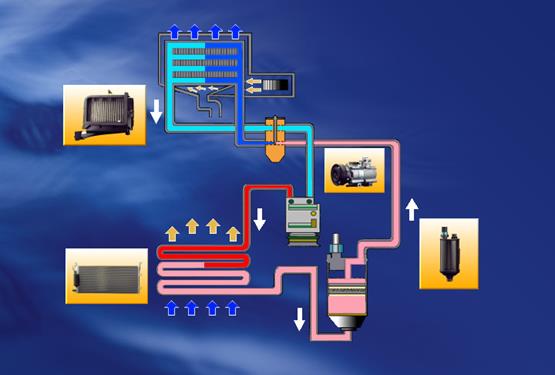

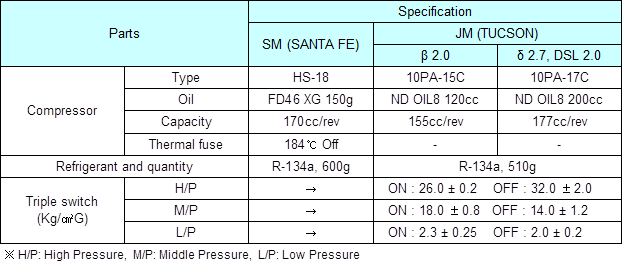

INTRODUCTION··············································· 3 ACTUATORS SPECIFICATION·············································· 5 - INTAKE DOOR ACTUATOR·························· 19 PARTS LOCATION··········································· 6 - TEMP. DOOR ACTUATOR···························· 20 INSTALL LAYOUT ············································· 6 - MODE DOOR ACTUATOR···························· 21 REFRIGERANT CIRCUIT ··································· 7 SENSORS PARTS IN ENGINE ROOM - FIN THERMO SENSOR ······························ 22 - CONDENSER··············································· 7 - INCAR SENSOR ······································· 23 - COMPRESSOR············································· 8 - PHOTO SENSOR······································· 24 - RECEIVER & DRIER······································ 9 - AMBIENT SENSOR ··································· 25 - TRIPLE SWITCH············································ 10 - AQS ························································ 26 PARTS IN CABIN - HUMIDITY SENSOR···································· 27 - HEATER UNIT··············································· 13 TEMPERATURE UNIT CHANGE···················· 27 - EVAPORATOR UNIT······································ 14 CONTROL LOGIC········································· 28 - EXPANSION VALVE ································· 15 SELF DIAGNOSIS - AIR FILTER·················································· 15 - DTC LIST & FAILSAFE································ 32 - BLOWER MOTOR········································· 16 PTC HEATER ·············································· 33 - POWER TR··················································· 16 - HIGH SPEED BLOWER RELAY························ 18

MEMO

INTRODUCTION Warning: Failure to follow procedures, or failure to adhere to warnings, cautions, and notices could result in personal injury and/or unnecessary vehicle damage/repairs. Cautions: 1. Before servicing any electrical components, disconnect the negative battery cable. Unless instructed otherwise, the ignition switch must also be in the “off” or “lock” position. 2. This air conditioner system contains R-134a, which requires special handling to avoid personal injury. Always follow the special handling instructions listed below: a) Always wear eye protection and wrap a clean cloth around fittings, valves and connections when servicing the refrigerant system. b) Always work in a well-ventilated area and avoid breathing refrigerant fumes. c) Do not weld or steam clean on or meat any air conditioner lines or components. d) Do not allow refrigerant to come in direct contact with your skin. If R-134a cones into contact with any part of the body, flush the exposed area with water and immediately seek medical attention. e) When using R-134a cylinders, reinstall the heavy metal screw cap after each use. f) Do not carry refrigerant containers in the passenger compartment of a vehicle when transporting R-134a g) When filling a small R-134a cylinder from a large one, never fill the cylinder completely. Always allow space above the liquid for expansion. 3. Prior to disconnecting, removing, or replacing any air conditioner lines or components, all refrigerant must be completely recovered using approved refrigerant recovery equipment. 4. R-12 is not compatible with R-134a. Using R-12 in this air conditioner system may cause system failure. 5. Do not remove caps from fitting until each component is ready for connection. 6. Do not release refrigerant into the atmosphere. Use your refrigerant recycling equipment whenever you need to discharge the air conditioner system. 7. Keep refrigerant container temperature below 40°C (104°F). 8. Do not expose refrigerant or refrigerant containers to fire or flames

Notices: 1. Reinstall fasteners in the same location from which they were removed. 2. Always use the correct part number fastener. 3. Always tighten fasteners and fittings to the correct torque value. Insufficient or excessive tightening can result in leakage or damage to the air conditioner system. 4. Any time the air conditioner system has been opened to the atmosphere, it should be properly evacuated before recharging with R-134a. 5. All parts should be at room temperature before uncapping to prevent condensation of moisture inside the components. 6. O-rings and seals must be in perfect condition. A burr, or dirt, on a sealing surface may cause a refrigerant leak. 7. When tightening O-ring fittings, the opposing fitting should be backed up with a wrench to prevent distortion of the seal and allow for proper tightening. 8. Remember to reinstall the service valve caps after charging the air conditioner system. 9. Flexible hose lines should not be bent to a radius of more than four times the diameter of the hose. 10. Flexible hose lines should not be allowed to come within a distance of 2.5inches(64mm) of the exhaust manifold. 11. Keep all tools and parts clean and dry. 12. Use protective covers to avoid damage to the body of the vehicle. 13. When installing air conditioner lines or electrical harness, route them properly to avoid contact with moving parts.

DESCRIPTION The A/C-Heater system combines heating, cooling, ventilation, dehumidifying. The heating system can be made simply as is utilized the heat generated by the engine. In the other hand the cooling system requires more complicated equipment to create cool air. When air is cooled, the moisture in the air condenses and forms water droplets that separate from the air. The airflow is controlled by manual type and automatic type. Full Automatic Temperature Control (FATC)features completely automatic control of discharge air temperature. FATC also controls the circulation and humidity of the air inside the vehicle. With FATC, the driver selects the temperature and the FATC functions to maintain that temperature, regardless of outside temperature changes. A FATC control module controls air conditioning, ventilating, heating, and defrosting systems. These electronic control systems automatically adjust doors, blower speeds, and compressor cycling.

PARTS LOCATIONS

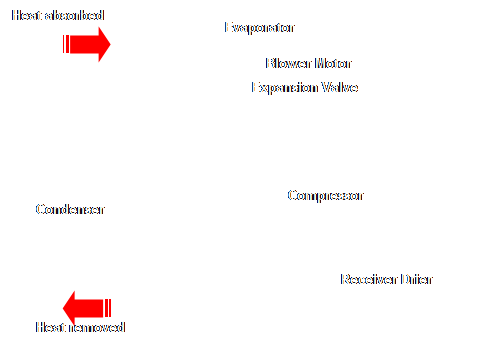

REFRIGERANT CIRCUIT

Date: 2016-01-03; view: 836

|

INSTALL LAYOUT

INSTALL LAYOUT