CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

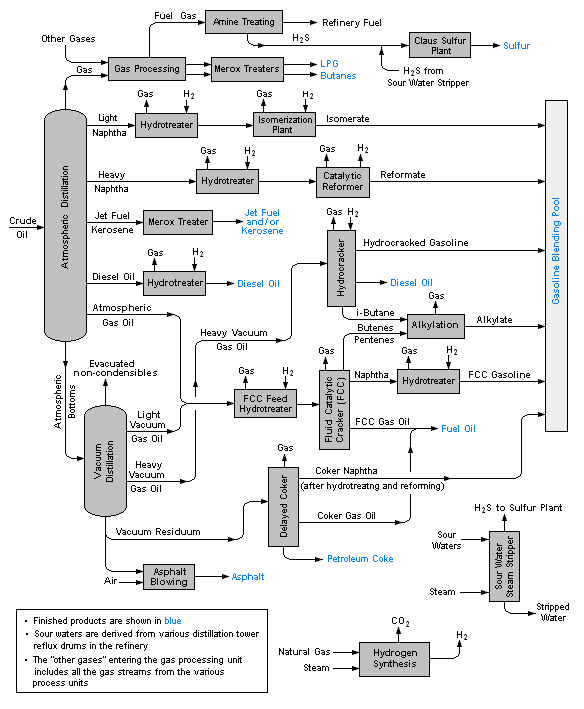

Procedural of plant process

Atmospheric Distillation Tower - At the refinery, the desalted crude feedstock is preheated using recovered process heat. The feedstock then flows to a direct-fired crude charge heater where it is fed into the vertical distillation column just above the bottom, at pressures slightly above atmospheric and at temperatures ranging from 650 degrees to 700 degrees F (heating crude oil above these temperatures may cause undesirable thermal cracking). All but the heaviest fractions flash into vapour. As the hot vapour rises in the tower, its temperature is reduced. Heavy fuel oil or asphalt residue is taken from the bottom. At successively higher points on the tower, the various major products including lubricating oil, heating oil, kerosene, gasoline, and uncondensed gases (which condense at lower temperatures) are drawn off. The fractionating tower, a steel cylinder about 120 feet high, contains horizontal steel trays for separating and collecting the liquids. At each tray, vapours from below enter perforations and bubble caps.

They permit the vapours to bubble through the liquid on the tray, causing some condensation at the temperature of that tray. An overflow pipe drains the condensed liquids from each tray back to the tray below, where the higher temperature causes re-evaporation. The evaporation, condensing, and scrubbing operation are repeated many times until the desired degree of product purity is reached. Then side streams from certain trays are taken off to obtain the desired fractions.

Products ranging from uncondensed fixed gases at the top to heavy fuel oils at the bottom can be taker continuously from a fractionating tower. Steam is often used in towers to lower the vapour pressure and create a partial vacuum. The distillation process separates the major constituents of crude oil into so called straight-run products. Sometimes crude oil is topped by distilling off only the lighter fractions leaving a heavy residue that is often distilled further under high vacuum.

Vacuum Distillation Tower - In order further to distill the residuum or topped crude from the atmospheric tower at higher temperatures, reduced pressure is required to prevent thermal cracking. The process takes place in one or more vacuum distillation towers. The principles of vacuum distillation resemble those of fractional distillation and, except that larger- diameter columns are used to maintain comparable vapour velocities at the reduced pressures, the equipment is also similar. The internal design of some vacuum towers is different from atmospheric towers in that random packing and demister are used instead of trays. A typical first-phase vacuum tower may produce gas oils, lubricating-oil base stocks, and heavy residual for propane deasphalting. A second-phase tower operating at lower vacuum may distill surplus residue from the atmospheric tower, which is not used for lube-stock processing, and surplus residue from the first vacuum tower not used for deasphalting. Vacuum towers are typically used to separate catalytic cracking feedstock from surplus residue.

Other Distillation Towers (Columns) - Within refineries there are numerous other, smaller distillation towers called columns, designed to separate specific and unique products. Columns all work on the same principles as the towers described above. For example, a depropanizer is a small column designed to separate propane and lighter gases from butane and heavier components. Another larger column is used to separate ethyl benzene. Small bubble towers called strippers use steam to remove trace amounts of light products from heavier product streams.

5.0 Process flow diagram The following is a simplified representation of the processes involved in the proposed refinery plant:

Date: 2015-01-29; view: 928

|