CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Unit 3. STRENGTH OF MATERIALS

Task I. Learn the words to the text:

Task III. Put each verb in brackets into the correct form: 1. Static, repeated and impact loads … the main types of loading (to be). 2. Hooke’s Law … that the unit stress in material is proportional to the unit strain (to state). 3. Strength of materials may be … mathematically (to express). 4. The moving body … the resisting body in a short period of time (to exert).

Task IV. Fill in the correct word or word combination from the list: resisting body, connecting rod, applies, are applied, is delivered, strains, concentrated load.

1. Hooke’s Law … also to compressive stresses and … . 2. … is load whose area of contact with the … is negligible in comparison with the area of resisting body. 3. Repeated loads … to the … of an engine when the engine is running. 4. The energy … to the resisting body by the moving body.

Task V. Read and translate the text. As to the manner in which loads are applied to a structure of machine they may be considered as static loads, repeated loads, impact and energy loads. 1. Static or dead loads are forces that are applied slowly and remain nearly constant after being applied to the body such as the loads on most buildings or the load applied to a bar in usual type of testing machine. 2. Repeated loads are forces that are applied a very large number of times causing a stress in the material that is continually changing, usually through some definite range. Such are the loads applied to the connecting rod of an engine when the engine is running, the wheel loads on a railroad rail as a train passes over the rail and similar ones. 3. Impact loads are forces that are applied to the resisting body in a relatively short period of time. An impact load, in general, is applied by a moving body when it comes in contact with the resisting body. The force exerted by the moving body and the period during which it acts in general cannot be determined. For the reason in some problems it is more satisfactory to calculate the stress and strain produced by an impact load from the energy delivered to the resisting body. Loads may be classified as distributed loads and concentrated loads. A distributed load may be uniformly distributed or non-uniformly distributed. A concentrated load is one whose area of contact with the resisting body is negligible in comparison with the area of the resisting body. Notes and

Task VI. Answer the questions to the text: 1. What are the main types of loading? 2. What is the static load? 3. Give an example of static load. 4. Where are the repeated loads applied? 5. Is it easy to calculate the stress and strain produced by an impact load? Illustrate your answer by an example. 6. Can we refer the impact loads to the concentrated loads? 7. Can we refer the static and repeated loads to the distributed loads? Explain your answer.

Task VII. Complete the sentences: 1. Repeated loads are the loads applied to the connecting rod of engine when … . 2. Impact loads are forces that are applied to … . 3. Loads may be classified as … . 4. Dead loads remain constant after being applied to the body such as … . 5. A concentrated load is one whose area of contact with the resisting body is … . 6. An impact load, in general, is applied by a moving body when it … . 7. A distributed load may be uniformly distributed … .

Task VIII. Read and translate the sentences. Agree or disagree with them: 1. Impact loads are forces that are applied a very large number of times, causing a stress in the material that is continually changing. 2. A distributed load is one whose area of contact with the resisting body is negligible in comparison with the area of the resisting body. 3. A concentrated load may be uniformly concentrated or non-uniformly concentrated. 4. It is easy to calculate the stress and strain produced by an impact load from the energy delivered to the resisting body by the moving body. 5. Static loads are applied to the connecting rod of an engine when the engine is raining. 6. Repeated loads are the loads applied to the wheel loads on a railroad rail as a train passes over the rail and similar ones.

Unit 4. WELDING

Task I. Learn new vocabulary:

Task II. Give synonyms to the following words: to obtain, mold, to deposit, to form.

Task IV. Read and translate the text. Welding is a method of causing fusing between two like pieces of metal to form one homogeneous mass of metal. Fusion of two masses of metal may be brought about by four different processes such as: 1 – Forge or blacksmith welding; 2 – Thermit welding; 3 – Electric welding; 4 – Gas welding. Forge is a process where by the two masses of metal to be welding are heated in a blacksmith’s forge or appropriate furnace until the metal reaches a plastic stage. At that time the two masses are quickly joined and fused together by force from a hand or power hammer Thermit Welding is not a common process. The process consists of a chemical reaction obtained by igniting finely divided alumimum and iron oxide. A mold is formed around the pieces to be welded and the metal is then preheated to a dull red colour. The aluminium and iron oxide are made molten by the chemical reaction which is started by a fuse. The temperature of the molten metal is high enough to fuse the broken sections, thus forming a homogeneous mass of metal. The equipment for thermit welding is simple and inexpensive but the quantity of the weld is not such as to recommend it for extensive use. The process can be used only on low carbon steels and wrought iron. Electric Welding. This type of welding is a pressure process, as it forge welding. It consists of heating to their plastic temperature the surface of parts to be joined, then applying pressure mechanically to achieve complete union of the parts. The heating is accomplished by passage of a heavy localized electric current. Alternating current of common commercial voltage is employed for this purpose. Gas welding. This process embraces several procedures. Joining of the base metals is achieved in most cases by fusion of a metal deposited between the surfaces of the metal to be joined, no pressure being required to accomplish the weld. In some cases the heated are fused without the deposit of metal.

Task V. Answer the following questions: 1. What is welding? 2. What are the main types of welding? 3. What is forge welding? 4. Thermit welding is a common process, isn’t it? 5. What process consists of a chemical reaction obtained by igniting finely divided aluminium and iron oxide? 6. Can the process of thermit welding be used on low carbon steels? 7. What types of welding are the pressure processes? 8. What kind of current is employed for heating in electric welding? 9. Is gas welding the pressure process? 10. When is a metal deposited between the surfaces of the metals to be joined used?

Task VI. Find the logical ending for each of the sentence beginnings:

Task VII. Determine the type of welding: 1. Joining of the base metals achieved by fusion of a metal deposited between the surfaces of the metals to be joined. 2. Process where two heated masses are quickly joined and fused together by force from a hand or power hammer. 3. The heating the surface of parts to be joined is accomplished by passage of a heavy localized electric current. 4. The process consists of a chemical reaction obtained by igniting finely divided aluminium and iron oxide.

Task VIII. Translate into English. 1. Çâàðþâàííÿ – öå ìåòîä ñïëàâëÿííÿ äâîõ îäíàêîâèõ êóñê³â ìåòàëó â îäíîð³äíó ìàñó ìåòàëó. 2. Îáëàäíàííÿ äëÿ òåðì³òíîãî çâàðþâàííÿ ïðîñòå ³ äåøåâå. 3. Çì³ííèé ñòðóì çâè÷àéíî¿ ïðîìèñëîâî¿ íàïðóãè âèêîðèñòîâóºòüñÿ ïðè åëåêòðè÷íîìó çâàðþâàíí³. 4. Íàãð³ò³ êðàþ ìåòàëó ç’ºäíóþòüñÿ ìåõàí³÷íî äëÿ òîãî, ùîá îòðèìàòè ì³öíå ç’ºäíàííÿ ÷àñòèí. 5. Òåìïåðàòóðà ðîçïëàâëåíîãî ìåòàëó äîñèòü âèñîêà, ùîá ç’ºäíàòè ÷àñòèíè â îäíîð³äíó ìàñó ìåòàëó.

Unit 5. TYPES OF ENGINES

Task I. Learn the following words and word-combinations:

Task II. Translate into Ukrainian: power stroke, exhaust stroke, compression stroke, induction stroke, gas engine, cylinder, two-stroke engine, motorcycles, six wheels, radiators engines.

Task III. Complete the dialogue. Use question and answering techniques given below: − … what type of engines there are in motor vehicles? − … There are … with petrol engines. And some motor vehicles … . − I wonder if there are … with gas … . − … a few … have gas engines. − And there are some … , aren’t there? − … . − Thanks for the information.

Task IV. Read and translate the text about different types of fuel and engines and check your answers. There are some basic types of fuel for motor vehicles. There is diesel fuel, there is petrol and there is fuel mixture. Most motocycles have two stroke petrol engines. But there are a few motocycles with four-stroke petrol engines. There are no motocycles with diesel engines. A lot of buses have diesel engines but only a few cars have such engines. There are also a few cars with two-stroke engines but most cars have four-stroke petrol engines. Most lorries have diesel engines. There are not many lorries with four-stroke petrol engines but there are no lorries with two-stroke engines. A lot of engines are at the front of the car. A few engines are at the back and very few are in the middle.

Task V. Answer these questions: 1. Are there any basic types of fuel for motor vehicles? What are they? 2. How many motorcycles have four-stroke petrol engines / two-stroke petrol engines? 3. Are there any motorcycles with diesel engines? 4. What motor vehicles have diesel engines? 5. How many lorries have diesel engines? 6. How many cars have four-stroke petrol engines? 7. Are there many lorries with petrol engines? Task VI. Complete the sentences, using a few, none, a lot, few, many, most: 1. There are a … motorcycles with four-stroke petrol engines. 2. … motorcycles have diesel engines. 3. There are a … cars with diesel engines. 4. … cars have two-stroke engines, … cars have four-stroke petrol engines. 5. Are there … lorries with four-stroke petrol engines? There are not … lorries with such engines. 6. A … of engines are at the front of the car. 7. There are a … engines at the back and there are very … engines in the middle.

Task VIII. Correct mistakes in the following sentences: 1. This plants produces motorcycles. 2. There are not much vehicles with two-stroke engines. 3. Are there some tools in that toolbox? 4. There are a lot of student in the workshop. 5. I have too questions to ask about types of engines. 6. Most lorries has diesel engines. 7. A lot of motor vehicles has petrol engines.

Task X. Read this extract for more information: There is a lot of carbon (about 85 %) in diesel fuel. There is also a lot of carbon in petrol. There is a little hydrogen in both these fuels. But there is little sulphur (about 1 %) in diesel fuel and there is no sulphur in petrol. There is a great deal of petrol (about 95 %) and a little oil (about 5 %) of the fuel mixture for two-stroke engines. There is no oil in the fuel for four-stroke engines. There is a great deal of air (90 %) and not much fuel (10 %) in the fuel and air mixture.

Task XI. Translate into English using your active vocabulary: 1. Ó äèçåëüíîìó ïàëüíîìó áàãàòî âóãëåöþ ³ ìàëî ñ³ðêè. 2. Ó á³ëüøîñò³ àëþì³í³ºâèõ ñïëàâ³â áàãàòî àëþì³í³þ òà ìàëî ì³ä³. 3. Ïàëüíå äëÿ ÷îòèðèòàêòíèõ äâèãóí³â íå ì³ñòèòü ìàñëà. 4. Ñê³ëüêè âóãëåöþ º â áåíçèí³? 5. ×è òè ìîæåø ìåí³ ñêàçàòè, ñê³ëüêè âóãëåöþ ì³ñòèòüñÿ ó äèçåëüíîìó ïàëüíîìó?

Unit 6. THE CAR, MAINTENANCE AND REPAIR

Task II. Answer the following questions: 1. Give five examples of machines. 2. Name five things except a car that have an engine. 3. Name several things a mechanic does. 4. What other mechanical parts of a car do you know? Task III. Practice in your vocabulary: What other things can we…

Repair Inspect Break down

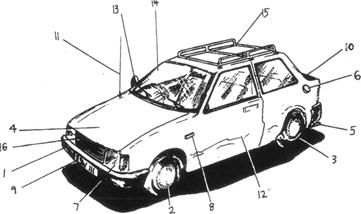

Task IV. Study the words for the parts of the car illustrated below, cheek them in your dictionaries. Then test yourself matching the words with the numbers on the picture:

Task V. Read and translate the text. A car is a machine. A machine has moving parts. Some machines are small and simple. Some machines are larger and have many parts in them. A car has an engine. The engine makes a car go. You don’t want the engine to break down, so take your car to a mechanic. He inspects the engine and does maintenance on it if necessary. If he finds something broken or old, he replaces or repairs it. Repairs are necessary to keep the engine running. One kind of maintenance is lubrication. Parts of the car need grease. Grease keeps dirt away. It helps the parts to move or turn smoothly. Lubrication means putting grease on parts that need it. In a car there are many parts that need lubrication. Lubrication is a regular part of the up-keep on a car. Such up-keep or maintenance is necessary to keep a car running.

Task VI. Put the words in correct order to make sentences: 1) broken / a / fixes / or / mechanic / engines / machines. 2) of / one / lubrication / types / is / the / maintenance. 3) break-downs / to stop / helps / maintenance. 4) lubrication / for / is / grease / used. 5) up-keep / necessary / car / regular / is / to keep / the / running.

Task VII. Match the machine parts (units) with their functions:

Task VIII. Imagine that you or your friend wants to buy a used car, so you decided to go to the local car market and to choose one. Reproduce the dialogue between you and the previous owner of the car you would like to buy. Use the following sentences and questions: − I want to buy a used car. − What is the mileage on the car? − Are you the original owner? − Does the car have automatic transmission / power steering / power brakes? − Have you had any accident with the car? − Are there any dents on the car? − Is there any rust on the car? − I would like to have the car checked up by mechanic before I buy it. − Are the tires in good condition? − How much are you asking for it?

Task IX. Correct the mistakes in the following sentences: 1. The speedometer is indicate 60 kilometers per hour. 2. We not performing mathematical operations. 3. Are the car moving now? 4. The tachometer does not used for measuring current. 5. Ann is driving a new car, is she? 6. The engine not producing any power now. 7. We studying the main components of a motor car.

Unit 7. ÒÓÐÅS OF FASTENINGS AND FASTENERS

Task III. Give English equivalents to the following words: çñóâ, òåðòÿ, âèêîðèñòîâóâàòè, ñèëà, ç’ºäíàííÿ, òèï, ðîçá³ðíèé, íåðóõîìèé, øòèôò, îòðèìóâàòè, òðèìàòè, çâàðþâàííÿ, ëèòòÿ, ïàÿííÿ, ä³ëèòè, êëèí, ð³çüáîâ³ ç’ºäíàííÿ, êîíñòðóêö³¿ ç’ºäíàíü, äèíàì³÷íå íàâàíòàæåííÿ, ãîëîâêà áîëòà ³ç çàãâ³çäêàìè äëÿ âèêðóòêè (øïë³íòè), îáìåæóâàòè ïîâîðîò áîëòà, ãàéêà ðîçòÿãàííÿ. Task IV. Read and translate the text. All fastenings can be divided into two classes – disconnectable fastenings and permanent joints. Disconnectable fastenings, in their turn, are effected by bolts, screws, keys, wedges, dowel pins. Permanent joints are obtained by means of press fits, shrink fits, rivets, welding, soldering and casting. The main standard threaded fasteners include bolts, studs, screws and nuts. The design forms and geometrical ratios of the heads of bolts, screws and nuts are versatile indeed. The choice of the design depends on the purpose of the joint. The heads may be hexagonal, square, countersunk, semi-circular, etc. They are also distinguished by the presence of the area that restricts the rotation of the bolt in tightening (for example, bolts with a larger semicircular head and a nib, and bolts with a hexagonal diminished head and a guide under head); by the method of clamping: externally, -internally (with an internal hexagonal socket) on the end-face (heads with splints for a screw driver) and by other features. Depending on the purpose of the joint and the conditions of assembly, nuts are selected differing in form (hexagonal, round, etc.), in thickness (normal, thin, thick). In various threaded joints, nuts can take external expanding load, which is compressive or tensile. The latter nuts are known as tension nuts and they belong to the special design. Washers placed under heads or nuts; protect the finished portion of the jointed members against damage during tightening.

Task V. Match the words in the left and right columns, translate the word combinations.

Task VI. Change the sentences according to the model. Model: Shafts are connected by gears. Gears connect shafts.

1. Moving parts are supported by bearings. 2. Plates and structural parts are joined by rivets. 3. The relative position of two parts is located by locating pins. 4. Two machine parts are held together by screw fastenings. Task VII. Match the words with their definitions:

Task IX. Answer the questions about the text. 1. What are machine parts held together by? 2. What do we call the fastenings, which hold two or more machine parts? 3. How many types of fastenings do you know? 4. Ñàn you name each of them? 5. What are disconnectable fastenings effected by? 6. What are permanent joints obtained by? 7. What do the main standard threaded fasteners include? 8. Are the design forms of the heads of bolts versatile? 9. What design forms of heads do you know? 10. What are the head distinguished by? 11. When are studs used? 12. What are washers used for?

Task X. Use the Ukrainian text to describe a picture with the riveted joint:

Unit 8. THREADED JOINTS

Task I. Learn the words:

Task II. Put the words into the correct columns: copper, screw, right-hand thread, assemble, fasten, nut, external thread, washer, lead, bolt, trapezoidal thread, tighten, iron, connect, retainer, left-hand thread, stud, obtain, aluminum, steel, taper, include, pin, square thread, transmit, gold, form, internal thread, dowel, silver, triangular thread, prevent, drive, key, hold, cylindrical thread, turn.

Task III. Fill in the blanks with the verbs in Passive Voice form according to the model.

Model: Screw fastenings are used for holding two or more machine parts, aren’t they?

1. Depending on the surface on which the thread is formed, they … (to classify) into cylindrical and taper. 2. Screw threads ... (to make) right-hand and left-hand. 3. Usually a right-hand screw thread ... (to use) in screw fastening. 4. There are many types of bolts and screws which ... (to use) for holding machine parts. 5. Disconnectable fastenings ... (to effect) by bolts, screws, wedges, pins, keys. 6. Permanent joints ... (to obtain) by means of fits, shrink fits, rivets, welding, soldering and casting.

Task IV. Read and translate the text. Part I A number of advantages offered by threaded joints favors their large-scale application in mechanical engineering. Threaded couples are highly reliable in operation, are convenient to assemble and disassemble, and can be obtained in a wide range adopted to various operating conditions and are relatively cheap to produce. The main standard threaded fasteners include studs, screws and nuts. They are used in combination with washers and nut blocks (retainers) of various designs, which prevent spontaneous unscrewing of threaded elements. Studs are used when the design of a joint provides no space for the bolt head or when a blind hole has to be drilled. Under dynamic loads a standard stud proves stronger than a standard bolt of the same size. As a rule, a stud is screwed in by means of two nuts – a nut and a locknut. For joints carrying heavy loads studs can be made from alloy steel. Screw heads can be slotted for a screwdriver or hexagonal or square head can be provided for a wrench. Standard nuts are manufactured in three versions: finished, semi finished and unfinished. In most machines hexagonal nuts are used. Square form is used only for unfinished nuts.

Part II Threads are applied for interconnection of machine parts and for transmitting motion from one part to another. When a thread is cut on the outside of a part it is known as an external or “male” thread. A thread is called an internal or “female” thread when it is cut inside of apart. Depending on the shape of the threading tool different profiles of thread are obtained, such as triangular, square or trapezoidal. In practice triangular threads are most widely used. The main elements of a thread are: the angle of the thread; the major, minor and pitch diameters; the depth and the pitch. The angle of the thread is the angle included between the sides of the thread and measured in an axial plane. The major or outside diameter of a thread is the distance between the two extreme outside points of the thread in the direction square to the axis. The major diameter is the largest diameter of the thread of a screw or a nut. The minor diameter, being the smallest diameter of the thread, is the distance between two extreme inside points of the thread measured at the right angle to the axis. The pitch diameter is the distance between two opposite parallel sides of the thread profile perpendicular to the thread axis. The depth of the thread is the distance between the crest and the base of the thread measured normal to the axis.

Task V. Fill in the words from the list below to complete the sentences and translate them into Ukrainian: external, bolt, internal, reliable, stud, trapezoidal, convenient, studs, known, cut, threads

1. When a thread is cut on the outside of a part it is known as ... . 2. ... are applied for transmitting motion from one part to another. 3. When a thread is ... inside of a part it is ... as ... . 4. Profiles of thread are as follows: triangular, square or ... . 5. The main standard threaded fasteners include screws, … and nuts. 6. Under dynamic loads a standard … proves stronger than a standard … . 7. Threaded joints are highly … in operation, are … to assemble and disassemble, and can be obtained in a wide range.

Task VI. Translate the sentences from Ukrainian into English using topical vocabulary:

Task VII. Work in pairs, ask and answer questions based on the text: 1. What is it known as an external (internal) thread? 2. What are threads applied for? 3. What types of profiles do you know? 3. What are the advantages of threaded joints in mechanical engineering? 4. What fasteners refer to the threaded ones? 5. Why do the mechanical engineers use different types of retainers in combination with threaded elements? 6. Why is the standard stud more favorable than the standard bolt? 7. What are the three versions of nuts? 8. What profile the threads can be depending on the shape? 9. Name the main elements of the threads. 10. What is the major (minor, pitch) diameter of the thread? 11. What is the angle of a thread and how it can be measured?

Task VIII. Read the text again. Put the following headings in the correct order according to the text. Then summarize the text using the arranged headings: 1. The definition of the major diameter. 2. Types of nuts. 3. The main elements of a thread. 4. The definition of the angle of a thread. 5. The types of screw threads. 6. Difference between a bolt and a stud. 7. Advantages of threaded joints application. 8. The definition of the pitch diameter.

Unit 9. BEARINGS

Task I. Learn the words:

Task II. Read the following English words and word combinations, give their Ukrainian equivalents: bearing failure; a need of replacement; a bearing with sliding contact; excessive wear; a sufficient bearing area; adequate lubrication; the bearing surface; a low melting temperature; metal-to-metal contact; the danger of overheating; cracking of the bearing metal; the specific bearing pressure; the presence of an oil film. Task III. Work in pairs, make up questions as in the model and answer them. Translate the sentences into Ukrainian.

Model: –We use an excavator to excavate the ground. –What is an excavator used for? –It is used for excavating the ground.

I. We use a thermometer to measure temperature. 2. We use a crane to lift up heavy loads. 3. We use a bearing to support a moving part and confine its motion. 4. We use journal bearings to carry load acting at right angles to the shaft. 5. We use thrust bearings to take load acting in the direction of the shaft axis. 6. We use rivets to obtain joints. 7. We use press, shrink and friction joints to connect machine parts more securely. 8. We use a wrench to tighten nuts. 9. We use a key to transmit torque between a shaft and a machine part assembled on it.

Task IV. Read and translate the text. A bearing is a machine part, which supports a moving part and confines its motion. That part of a shaft, which rotates in a bearing, is called a journal. Bearings carry load acting at right angles to the shaft axis. Bearings in which one rubbing surface slides over another are called plain bearings. They may be divided into two classes: À. Those with a continuous rotary motion and B. Those with an intermittent motion. Ball bearing consists of two rings: an inner ring and an outer ring between which there are hardened steel balls spaced in ball retainer or cage. In rotating machines the balls are spaced so that they do not touch each other, thus reducing wear and noise. They require an absolutely parallel raceway to roll upon. The failure or need of replacement of à bearing with sliding contact may be due to: a) excessive wear; b) overheating; ñ) cracking of the bearing metal. Excessive wear is caused by metal-to-metal contact. It can’t be entirely eliminated but can be reduced by providing a sufficient bearing area and by adequate lubrication. Overheating if not stopped in time, may result in melting the bearing surface. Overheating is also caused by metal-to-metal contact. Lubrication decreases the danger of overheating. The object of lubricating a bearing is to interpose a liquid film between the rubbing surfaces and thus to reduce the frictional resistance. This is why one of the main problems of a bearing design is to reduce friction by proper lubrication. Cracking of the bearing metal is due to heavy shock loads. The remedies are to lower the specific bearing pressure. However even in this case the presence of an oil film is useful as a shock absorber.

Task V. Combine the words in the right and left columns to form word combinations:

Make up five interrogative sentences with the formed word combinations and answer them.

Task VI. Complete the dialogue as in the example. Act out the dialogue in pairs.

Example: À. What’s this? Â. This is a screw. A. What’s a screw? B. It’s a metal peg, which is driven into metal for fastening and holding things together.

A: ... ? B: This is a bearing. A: Do know what is it used for? B: ... . À: ...? Â: This is a bolt. À: ... ? Â: It’s a metal pin that is used to join parts together. A: ... ? Â: This is a wrench. A: ... ? B: It’s a tool, which is used to grip and turn nuts, bolts, etc. A: ... ? B: This is a nut. A: ... ? B: It’s a small piece of metal which is used to screw on the end of the bolt. A: ... ? B: This is a formula. A: ... ? B: It’s a statement of a rule, fact, etc. A: ... ? B: It’s a plane figure. A: What kind of figure is it? B: It’s a triangular. A: What does the word “distance” mean? B: The word “distance” means the measure of space between two points, places, etc. A: ... ? B: It’s a thread. A: ... ? B: The word “thread” means spiral ridge round a screw.

Task VIII. Ask the questions to the sentences below and answer them. Begin your answers with the following affirmative (negative) words or word combinations: certainly, of course, naturally, surely, (not) quite so, that’s (not) right, that’s just it, I (don’t) think. 1. Overheating may result in melting the bearing surface. 2. Cracking of the bearing metal is due to heavy shock loads. 3. It is necessary to interpose a liquid film between the rubbing surfaces in order to reduce the frictional resistance. 4. All bearings are divided into two classes. 5. Lubrication reduces the danger of overheating and excessive wear. 6. Excessive wear can be entirely eliminated. 7. The ball bearing always requires the parallel raceway.

Work in pairs, ask and answer the questions on the text. 1. What is a bearing? 2. What is a journal? 3. What classes are bearings divided into? 3. What is the object of lubricating a bearing? 4. Why is a liquid film interposed between the rubbing surfaces? 5. What is one of the main problems of a bearing design? 6. What causes the failure of bearings? 7. Can the excessive wear be entirely eliminated? 8. What is the result of overheating of the bearing? 9. What is the cracking of the bearing due to? 10. How can we avoid of cracking? 11. What does a ball bearing consist of? 12. What is there between rings? 13. How are the balls spaced in rotating machines? Unit 10. GEARS AND CLASSIFICATION OF GEARS

Task I. Learn the words:

Task II. Arrange the words in pairs and translate them into Ukrainian:

Task III. Give English equivalents to the following words and word combinations:

Task IV. Read and translate the text. There are a number of different kinds of mechanisms or components that transmit motion or change it in one way or another. Gears play such an important part in machines that they have become the symbol for machinery. They are frequently used to reduce or increase the speed of a motion and they can also change the direction of motion. By classifying gears according to the shape and arrangements of their teeth we discover four basic types. The simplest and the most common is the spur gear. Spur gears have teeth that are straight and parallel to the axis. In helical gears the teeth are at such an angle to the wheel that they form helices. These gears are particularly useful for transmitting power at high speeds. They are also used to change the direction of motion, most frequently when the axes are crossed through a 90° angle. In a bevel gear the teeth are slanted in relation to the plane of the wheel. Bevel gears are useful in changing the direction of motion, the change being proportional to the angle of the beveled surface. Bevel gears are used to connect two shafts whose axes intersect each other. Two types of bevel gearing are in general use, straight-toothed gears and spiral tooth gears. Bevel gears are not interchangeable and in most cases the axes of the shafts form a right angle but they may intersect at any desired angle. The fourth basic type is called the worm gear. Basically a pare consists of the gear itself, a wheel with teeth which meshes with a worm – a screw which is a helix wrapped around a cylinder. Worm gears are used primarily for changing the direction of axial motion. Friction gears depend on their driving motion upon the friction of driving wheel, or driver against its mate. The friction surface of a driver should be of a comparatively soft material, such as wood, fiber, leather, paper or rubber, while that of the follower is usually made of cast iron. Friction gears are used for light and medium power in machinery or where a reversed motion is necessary. The disadvantages of friction gears are the thrust on bearings and slippage, resulting in a comparatively low efficiency.

Task V. Give English equivalents to the word combinations in the left column and make up the sentences with them:

çóá÷àñòà ïåðåäà÷à

Task VI. Complete the following sentences with the appropriate word or phrase. 1. Gear devices are essential elements in large devices as well as … . 2. Gears are mostly used to change the direction of motion and to … . 3. … depend on their driving motion upon the friction of driving wheel. 4. There are two types of bevel gearing: … , and they are used to connect two intersecting shafts. 5. The teeth of the spur gear are … . 6. Worm gears have two components: … , and are used to … . Task VII. Translate the following sentences from Ukrainian into English, using topical vocabulary: Task VIII. Answer the questions about the text: What do we call a gear? 2. How many types of gears can you mention? 3. What are they? 4. Where are gears used? 4. What is a friction gear? 5. Should the friction surface be of comparatively soft material? 6. When do we use friction gears? 7. What criterion is the classification of gears based on? 8. What are the disadvantages of friction gears? 9. When do we use bevel gears? 10. What do you know about spur gears? 11. What are the types of bevel gears? 12. What are the helical gears used for?

Unit 11. CARE OF THE ELECTRICAL EQUIPMENT

Task I. Learn the new words and word combinations:

Task II. Give synonyms to the following verbs. Example: to operate – to perform, to carry out, to do. To remove, to place, to get heated, to deserve, to undertake.

Task III. Make up sentences of your own using the following words and word combinations: 1) to remove, heating sparking; 2) to place, rotating machine, solid foundation; 3) conductor, insulation; to get heated; 4) damage, conductor, to remove.

Task IV. Translate into English:

Task V. Read and translate the text. As a rule electrical equipment operates reliably. Still it does not mean that it deserves no attention. It is necessary to give the equipment frequent inspection, keep it well cleaned, lubricated and repaired. Undue heating, vibration, sparking should be immediately removed. Heating may be due to overload or to a short circuit between turns, lack of oil in bearings. Vibration may be due to unproved foundation, unbalance in the moving parts of the machine. Conductors may get heated because of overload or by reason of damage of the insulation of the conductor. An electrical machine of any kind requires certain conditions under which it may operate reliably: temperature and freedom of access of surrounding air, need for protection against dirt, dust, type and duration of load, etc. Rotating machines should be placed on solid foundations. Conductors should be protected against mechanical damage. All measures of safety precaution must be undertaken.

Notes and commentary: keep it well cleaned – òðèìàòè â ÷èñòîò³ undue heating – íàäì³ðíå íàãð³âàííÿ may be due to – ìîæå áóòè ÷åðåç measures of safety precaution – çàõîäè ç òåõí³êè áåçïåêè

Task VI. Answer the questions: 1. Does the electrical equipment deserve attention? 2. How must we keep the electrical equipment? 3. What are the main reasons of heating? 4. What are the conditions under which electrical machine may operate reliably? 5. What are the main reasons of vibration? 6. What must we undertake using electrical equipment?

Task VII. Translate into English:

Task VIII. Translate the following sentences into English:

Unit 12. PROTECTION AND CONTROL EQUIPMENT

Task I. Learn the words and phrases:

Task II. Give the Ukrainian equivalents to the following words: contactor, direct current, the knife switch, equipment, generation, contactor, circuit, to remove, distribution, safety switch, to enclose, to make the circuit, in series, to break the circuit, to keep the current from being excessive. Task III. Match the Ukrainian equivalents with the English words:

Task IV. Read and translate the text. In electrical systems for the generation, distribution and use of electrical energy, considerable control equipment is necessary. It can be divided into two classes: a) equipment used at the generating and distributing end; b) equipment used at the receiving end of the system. Safety switches are used at the point where the power enters a building. They are of the knife type and are usually enclosed in metallic boxes. A magnetic contactor is used to make and break the circuit at the points where considerable power is used. An automatic starter is a device which is used to keep the current from being excessive while the motor is obtaining full speed. It is a kind of a resistance inserted in series with the direct current in series with armature. As the motor obtains speed it gradually removers.

Task V. Answer the questions to the text: 1. What control devices in electrical systems do you know? 2. How can the control equipment be divided into? 3. Where are safety switches used? 4. What is used to make and break the circuit at the points where considerable power is used? 5. What is an automatic starter?

Task VI. Fill in blanks the necessary words: 1. Considerable control equipment is necessary in electrical systems for … . 2. Safety switches are of the … and are usually … . 3. A magnetic contactor is used to … at the point where considerable power is used. 4. An automatic starter is a device which is used … while the motor … 5. Automatic starter is a kind of a resistance … .

Task VII. Translate into English:

Task VIII. Retell the text.

Task IX. Sum up the main information from the text in writing. Unit 13. MEASURING DEVICES

Task I. Memorize the following words and word combinations:

Task II. Match the words with their meanings:

Task III. Read and translate the text. Ammeters measure the current flowing in a circuit and normally have scales which are calibrated in amperes, milliamperes or microamperes. Voltmeters are used to measure the potential difference between two points in a circuit. The calibration of voltmeters is usually in volts, millivolts or microvolts. The main difference between the two instruments of the same type is in the resistance of the operating coil. Wattmeters. – The measurement of the power in a direct current at any instant can be achieved by means of an ammeter and voltmeter as the power in watts is the product of the current and the voltage. With alternating current circuits, however, the instantaneous values are always changing. To measure alternating current power correctly, therefore, it is necessary to use the third instrument to measure the phase difference. The normal practice, however, is to combine these three instruments in one which will give reading of power in watts.

Task IV. Answer the following questions: 1. What measuring devices do you know? 2. What do ammeters measure? 3. What is the calibration of ammeters? 4. When are voltmeters used? 5. What is the calibration of voltmeters? 6. Is the power in watts the product of the current and voltage? 7. What is used to measure the phase difference? 8. Try to describe the difference between ammeters, voltmeters and wattmeters.

Task V. Complete the following sentences with the appropriate word or phrase: 1. … the potential difference between two points in a circuit. 2. The calibration of ammeters is usually in … . 3. With alternating current circuits the instantaneous values … . 4. To measure alternating current power correctly it is necessary … .

Task VI. Make a short summary of the text.

Date: 2015-01-02; view: 2172

|

ôðèêö³éíà ïåðåäà÷à

ôðèêö³éíà ïåðåäà÷à