CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Nuts and split pins

Conventional plain nuts are usually six-

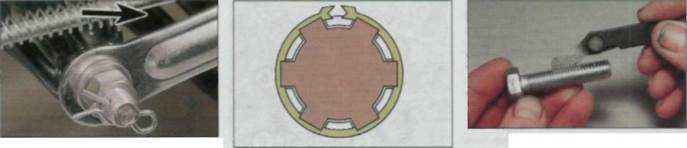

Self-locking nuts either have a nylon insert, or two spring metal tabs, or a shoulder which is staked into a groove in the shaft -their advantage over conventional plain nuts is a resistance to loosening due to vibration. The nylon insert type can be used a number of times, but must be renewed when the friction of the nylon insert is reduced, ie when the nut spins freely on the shaft. The spring tab type can be reused unless the tabs are damaged. The shouldered type must be renewed every time it is disturbed. Split pins (cotter pins) are used to lock a castellated nut to a shaft or to prevent slackening of a plain nut. Common applications are wheel axles and brake torque arms. Because the split pin amis are deformed to lock around the nut a new split pin must always be used on installation - always fit the correct size split pin which will fit snugly in the shaft hole. Make sure the split pin arms are correctly located around the nut (see illustrations 2.5 and 2.6).

Bend split pin (cotter pin) arms As shown (arrows) to secure A castellated nut

2.6 Bend split pin (cotter pin) arms as shownto secure a plain nut Caution: If the castellated nutslots do notalign with the shaft hole after tightening to the torque setting, tighten the nut until the next slot aligns with the hole - never slacken the nut to alignits slot. R-pins (shaped like the letter R), or slip pins as they are sometimes called, are sprung and can be reused if they are otherwise in good condition. Always install R-pins with their closed end facing forwards (see illustration 2.7). REF»6 Tools and Workshop Tips

Circiips (seeillustration 2.8)

Circiips (sometimes called snap-rings) are used to retain components on a shaft or in a housing and have corresponding external or internal ears to permit removal. Parallel-sided (machined) circiips can be installed either way round in their groove, whereas stamped circiips (which have a chamfered edge on one face) must be installed with the chamfer facing away from the direction of thrust load (see illustration 2.9).

Date: 2016-01-14; view: 728

|

2.7 Correct fitting of R-pin. Arrow indicates forward direction

2.7 Correct fitting of R-pin. Arrow indicates forward direction