CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Shafts for all Purposes

Sinking Shafts Sink shafts are passageways sunk from the surface downwards, or underground from one level to another. The majority of the sink shafts are driven vertically.

The design of the cross section of the shaft principally depends on the quality of the rock. Nowadays, most shafts have a circular cross section, which gives better distribution of the rock pressure and decreases the need for reinforcement, especially at depth. The most common drilling and blasting methods are benching and blasting with pyramid cut. The benching method is a fast and efficient method, as the time-consuming cleaning of the floor between the blasts can be minimized. It is also easy to keep the shaft free from water, as a pump can always be placed in the lower blasted part of the shaft. The drilling and charging pattern is similar to that of smaller surface blasts. The burden and spacing vary with the hole diameter, but the drilling pattern is more closely spaced than for surface blasting, due to higher constriction. Shaft sinking with pyramid cuts is similar to tunnel blasting with V-cuts. The drilling is done with a drill-ring, which comprises a circular I-beam to which the drilling machines are fixed. The drill-ring may be fixed to the shaft walls with bolts, and the cut will be conical. Date: 2015-12-24; view: 705

|

Shafts are either sunk downwards or raised upwards. In mining, they form a system of vertically or inclined passageways, which are used for transportation of ore, refill, personnel, equipment, air, electricity, and ventilation. In underground construction and tunnels, shafts are driven for penstocks, cable ducts, ventilation, elevators, and surge chambers. In addition, they are driven as glory holes for transportation of material, which may not be accessible by any other means. For shaft raising. Atlas Copco has a choice of handheld pneumatic machine mounted on stoping airlegs. For sinking vertical shafts, the company produces rigs with up to nine machines, capable of parallel hole drilling.

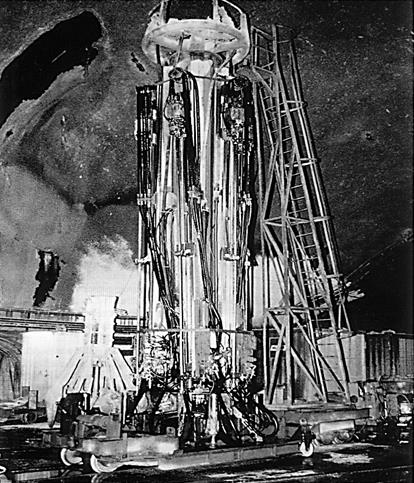

Shafts are either sunk downwards or raised upwards. In mining, they form a system of vertically or inclined passageways, which are used for transportation of ore, refill, personnel, equipment, air, electricity, and ventilation. In underground construction and tunnels, shafts are driven for penstocks, cable ducts, ventilation, elevators, and surge chambers. In addition, they are driven as glory holes for transportation of material, which may not be accessible by any other means. For shaft raising. Atlas Copco has a choice of handheld pneumatic machine mounted on stoping airlegs. For sinking vertical shafts, the company produces rigs with up to nine machines, capable of parallel hole drilling. Shaft sinking is one of the most difficult and risky blasting jobs, as the work area is normally wet, narrow and noisy. Furthermore, the drilling and blasting crews are exposed to falling objects. The advance is slow, as the rock has to be removed between each blast with specialized equipment with limited capacity. The blasted rock must be fragmented, to suit the excavation equipment.

Shaft sinking is one of the most difficult and risky blasting jobs, as the work area is normally wet, narrow and noisy. Furthermore, the drilling and blasting crews are exposed to falling objects. The advance is slow, as the rock has to be removed between each blast with specialized equipment with limited capacity. The blasted rock must be fragmented, to suit the excavation equipment.