CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Devices for measurement of surface properties of products

Plan of the lecture:

1. Methods of measurement of adhesion

2. The requirements adhesiometer

3. Devices for determination of coefficients of friction.

Purpose of the lecture: get acquainted with devices for measuring the surface properties of products

1. Methods of measurement of adhesion. Instruments and methods for measuring the adhesion based on destruction seam adhesive by application of external force (Fig. 2.16). By way of application efforts distinguish the methods of the assumption of uniform and non-uniform) and shift.

Most often adhesiometer for food products is implemented diagram on Fig. 2.16 and. It may be different ways of application of force and registration tear efforts. For example in the instrument of Nikolaev «instantly» comes off the top disk using a lever mechanism; in the device Coleman gradually comes off the lower disk during the filling of suspended him containers with water. Splitting contacting bodies may be three options: adhesive - on a boundary of the product - a wall, the cohesive - layer product - and mixed.

Devices and methods of measuring the adhesion based on destruction of adhesive compound be-by the application of external force. Determination of the adhesion properties of the products, depending on the method of application of force, manufactured by the method of isolation and shift method. For these methods can be applied various methods of their implementation, which is schematically represented in figure 30, where the food product (adhesive) shows the dark, and the material with which it is in contact (substrate) - bright.

| ||||||||

| ||||||||

| ||||||||

| ||||||||

|

Fig. 2.16. Schematic diagrams of instruments for measuring the adhesion strength:

a) uniform separation; b) non-tensile, bending of sheet materials; g) the means of stratifying materials; d) ways shear fracture; (e) the means of shear fracture torsional

The division (separation) of contacting bodies, depending on their nature and the technological conditions may be on the border of contact (adhesive gap), one layer of the product (cohesive tearing) or mixed (adhesive-cohesive gap). Given these circumstances, before tests necessary to carefully prepare the samples of the studied product (adhesive) and material (substrate) with whom to contact. For adhesive tear broken external links between material and product, which characterize the energy of the free surface. When cohesive isolation violated internal communication in the product, which depend on the energy of the interaction between the elements of the structure in conditions of volume of stress state. Food net adhesive gap is rare, so in experiments measure the breakout of material (substrate), often without specifying its type.

The adhesion value of the affected: technological properties of the product itself (temperature, humidity, composition and other); mark of the material of construction; the roughness of the surface material of the measuring conditions (geometrical, kinematic and dynamic parameters of the device).

Tibamanya made to adhesiometer. The requirements adhesiometer:

- the readings should be primary, i.e. they do not require prior calibration on any reference material and can be expressed in absolute units;

- before you measure a product should stick to the substrate for establishing contact and removal from him air bubbles;

- the application of the product specified thickness on the plate of the appliance must be carried out with the help of the template to eliminate the influence of the thickness of its adhesive properties;

- in devices must be provided by the replacement of plates in order to determine the effect of brand material of the plates and the degree of its processing (roughness) on the strength of molecular contacts;

- devices must allow the opportunity of a variation, rate of application of force detachment or shift wide, to establish the effect of breakout forces on the strain distribution and efforts between the plates and the product.

Characteristic of adhesion product can have the following values: power off, referred to the contact area; the work of the breakout, related to the area of contact; the time required for the destruction of communication between the substrate and the type of adhesive under the action of a given load. Specific minimum force called adhesive strength, adhesive voltage (pressure), the pressure of adhesion or specific adhesion.

Devices for determination of the adhesion characteristics by the method of application of the load is divided: on adhesiometer with constant separation, adhesiometer with instant off, and savegames. Uniform tear-off load perpendicular to the plane of the substrate, and the adhesion is characterized by normal force, assigned to the unit area of contact, i.e. normal voltage. When shift is determined tangential stresses relative displacement of layers of adhesive relative to the substrate. For the study of adhesion food visco-plastic materials are used instruments based on the method of normal rupture.

The adhesion meter B.A. Nikolaev (figure 31). The device is simple: designed on the principle of balance and is designed for the study of adhesion viscous food products. It consists of the measuring plate (substrate) (1)executed in the form of a disk, double-arm lever (2), to which on the one hand hanging from the substrate, and on the other goods (3) and the base unit (5). Between the disk and the basis of the applied adhesive (4). During the test, gradually increasing the weight of the cargo (3), gain margin (disk 1) from an adhesive (4). By results of measurement expect the viscosity of the material.

The adhesion meter J.V. Klapovsky (figure 31, b). The device is intended for determination of the adhesion properties of viscous food materials, in particular of candy mass. It is simple and reliable in operation.

The device consists of a lever (7), to him pinned vertical rod (8), located in the guide, which through measuring elastic ring (9) is fixed plate (10). To create a prior contact are the securing screw (5) and stop (4). Breakout force of measure using strain gauges (6) pasted on measuring elastic ring (9). The movement of the plate (10) is measured by the photodiode (3), the blind (2) covers part of the light beam illuminator (1)changing the illumination of the photodiode. The investigational product is placed in a special container (11), which has a cover with hole that with a small backlash comes plate substrate.

|

|

Figure 31 adhesiometer

:a) - adhesiometer B.A.Nikolaeva b) - adhesiometer Yu.V.Klapovskogo .

During the tests, strain gauges readings and after the photodiode gain recorded on a loop oscillograph , allowing capture the time variation of breakout force and movement of the substrate relative to the adhesive. Universal adhesiometer MTIMMPa ( IADC ) . Device (Figure 32 ) is designed to measure the adhesive properties of products and allows you to change a wide range of geometric, kinematic and dynamic measurements , and other parameters .

The device has a housing (1 ) , the lifting table (2) with a micrometric screw for attaching the lower plate ( substrate) (3 ) and a device for separation of product and the loading of the upper plate . The upper fixed plate holder which is mounted on tenzobalke (4 ) and has a shank for alignment of the movable part of the system. In the upper part of the appliance housing on a transverse beam fixed sleeve (8 ) into which is inserted the cross member ( 7) with the shank ends of which are fixed on the rings ( 6). On top of the housing is mounted a drive shaft with a set of pulleys (10 ) of different diameters. Vertically tenzobalka will mix earrings that end prisms and pivotally mounted on a crossbar with shank . Last moved into by a thread bushing (9 ) and a set of pulleys , which are driven by an electric motor through a reducer ( not shown ) . To create a contact tenzobalku preliminary set loads ( 5). In each series of experiments tenzobalku calibrated to give the dependence : the load - deflection " bunny " on the waveform .

|

Figure 32. Universal adhesion meter Mtimmp

The device parameters: pressure prior contact from 300 up to 3.5·10 PA; the duration of the preliminary contact- 3; 60; 180; 300; 600 with; take-off speed of the upper plate of the product -- 0,00167; 0,00358; 0,0093;

0,0193 m/s; the plate surface - 0,0005; 0.0007; 0.0010; 0.0015 m ; material plate - steel St. 3, stainless steel NT, aluminium, cast iron, fluoroplastic-4, brass; the height of a product - from 0.00003 to 0.003 m; the relative error of the instrument - + 4 %.

The adhesion meter AM-1. For the determination of the adhesion properties of the products based on the method of the displacement and is intended for investigation of viscous-Plastinin materials, in particular for the test.

The device consists of the frame (1), clamp (2), rod (3), sleeve (4), elastic element (5) with a fixed strain gages, cargo (6), matrix (7) the preparation and platform (8).

During the test, matrix with baked test harvesting is attached to the vertical shaft, then the workpiece is pressed two semiconical pads. When the platform rotation around the vertical axis is the shift of the workpiece relative to the stationary matrix. The rise of a matrix by means of cargo allows you to define a breakout.

3. Devices for determination of coefficients of friction. The devices used to determine coefficients of friction, food called tribometer.

|

Figure 33. The adhesion meter AM-1

The ratio of external friction food materials depending on the rheological properties, the condition of the friction surfaces and the sliding velocity is defined in different ways. The classical type of instrument for measuring the strength of the external friction is a pair of bodies in contact surfaces, the area of which can be from fractions of square millimeters to tens of square centimeters. However, one of the bodies is shifted relative to another. Force applied to offset (friction) of one body relative to another, measured strain, torque or any other sensors.

I. Century Kragelskii putting in the basis of geometrical and kinematic principles, suggested known methods of determination of the coefficient of friction divided into four groups, which in the form of diagrams shown in figure 34.

The first group methods in which one plane progressive moves relative to the other plane (figure 35. a, b, C). Under the scheme, the product goes on moving the studied surface, while the friction force is measured by the dynamometer any type. Therefore the most common method used to determine the friction Tverdovsky materials: meat, fish, bread, etc.

Scheme b, the product is transported by cargo on investigated static surface. The friction force in this case is equal to the minimum amount of equipment required for a uniform product flow. This method determines the coefficient of friction products such as cheese, fish, confectionery and other

Under the scheme, the product is sliding down an inclined surface. The friction coefficient is determined by the smallest angle of inclination of the surface of the test constructional material on which the slides food product. This method allows to determine the static coefficient of friction for cheese, crackers, dry food. The method is insufficiently precise and wide application not received.

| |||||||

| |||||||

| |||||||

| |||||||

Figure 35. Methods of measuring the force of friction of:

a), b), C) - in directional movement of planes; d), e) - at rotation of one of friction pairs;

e) at the contact of the generatrix of the cylinder with the plane; w) - when switching cylindrical or flat flexible surface of the cylindrical surface

The second group of methods in which one of frictional pairs rotates. Under the scheme g of the product is fixed to the elastic Belocca onto the rotating surface of the investigated material. This method determines the coefficient of friction of meat, fish, etc. Under the scheme d product lies on a rotating disk, studied structural material slides on a rotating product. The friction force is determined by torque transferred from the disk to the sample.

The third group of methods in which is generatrix of the cylinder is in contact with the plane. Under the scheme e beam performing oscillatory motions on two rotating towards each other rollers.

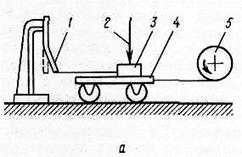

The fourth group - the methods in which one cylindrical or flat flexible surface moves on a cylindrical surface (figure 36 W). The tribometer trolley figure 35. a). The device allows to determine the friction force and calculate the true and effective coefficients of the external friction. It consists of (1) for the measurement of the friction force (tentalce), devices (2) to create pressure contact, a frame with the investigational product (3), trolley mounted on it with a plate (4) and electric drive (5) with a pulley.

During the trials of the investigational product is placed in a frame, mounted on a flat surface plate truck and include the electric motor. Thread negativitis on the pulley starts to move the cart, and with it the product, enclosed in a frame, from which through the thread is passed tentalce, which under the force unbent from its original position. When moving the cart, efforts between the frame with the product and tentalce increase and reaching critical values begins frame slide with the product on the surface of the plate truck. This deflection tentalce will remain at the same level constant. The frictional force arising between the product and the plate is fixed to the deviation of tentalce, the value of which by means of strain gauges attached to it, is transferred to the tape of the oscilloscope. To change the speed of the truck has a four-pulley, which is winded thread. The instrument allows changing the geometric (the size of the surface area of contact, surface finishes and others), motion (speed shift trucks, time prior contact, etc.) and dynamic (pressure preliminary contact, the slew rate of the power and other) factors. The device is equipped with a set of changeable plates produced from different material.

Figure 36. Tribometers:

a) - tribometer with trolley b) - Tribometer parallel offset plates,

c) - tribometer to drive the moving part of the hydraulic cylinders.

Tribometer parallel offset plates (Figure 36 b). Device intended to determine the adhesion characteristics of the solids , such as cheese. It consists of a freight unit (1 ) for measuring the frictional force , the device (2 ) for creating a pressure contact plate (4 ) below and above which , a layer of the test product (3 ) , a cargo actuator ( 5) and a device for measuring displacement in the form of a dial indicator (6). Drive plate carried by cargo premolding samples screw mechanism . Offset plates measured dial indicator . The device can be used for measurement of friction as well as viscosities at low velocity gradients .

Tribometer drive the moving part of the hydraulic drive (Figure 36 ) . The instrument is designed to determine the force of friction in a small contact area and large normal efforts . It consists of tenzobalki (1 ) , the device (2 ) for creating a pre- contact of the plate ( 4) and the hydraulic drive . When measuring high frictional forces hydraulic drive system has an advantage over electric furthermore provides a hydraulic stepless speed.

Currently, enough meat products , the nature of adhesion is not clear , although the matter the subject of numerous studies and several hypotheses to explain the physical and the mechanical nature of adhesion phenomena.

Date: 2015-12-24; view: 1667

| <== previous page | | | next page ==> |

| Fig. 2.17. Methods of measurement of the external friction | | | The management rheology |