CATEGORIES:

BiologyChemistryConstructionCultureEcologyEconomyElectronicsFinanceGeographyHistoryInformaticsLawMathematicsMechanicsMedicineOtherPedagogyPhilosophyPhysicsPolicyPsychologySociologySportTourism

Fabricating and erecting issues

Sequent stage is fabricating which is followed directly by erecting and could be going at the same time. Correspondingly first principal operation provides production of construction elements from crude materials. At this stage assembling and fitting of prepared details also possible if appropriate instructions were conceived previously. Erection is assuredly important stage and it includes different variety of operations as handling, transportation, rigging, hoisting, element connecting. (5)

Erection engineer with builder lead control of the erection process. Critical regard should be given to avoid progressive collapse which is irreversible damage of relatively insignificant part leading to massive collapse of other connected parts. To prevent such dramatic consequences simple precautionary measures should be taken and controlled. For example, decent order of erection and master estimating of structure balance must be performed in row with timeous tying, shoring and bracing of unfinished construction. Measures must be taken to provide safety of steelwork in case of unexpected collapse of one element due to change of loads conducted through structure. In case when steel roof or wall bracing system ply whole building structure additional attention should be paid by designer and erector at arrangement of works and safety measures until completion of connected activities. Furthermore, some exceptional loads could occur in the flow of erection, like explosions on the construction site or machine and vehicle accidents. (6)

It is important to realize prevalent problems simultaneously with their solutions which potentially common and connected with deterioration of steel at the time of erection of building. To demonstrate, further the list of problems caused by quality defects.

Firstly, fabrication of elements as essential part of building production could lead to assorted deformations of steel. Avoiding flame cutting but using for example submerged arc welding prevent edge of detail from wave deformation. Possibility of bending and twisting during formation should be examined as well. Similarly influence of deformation after correcting, bending, cutting, perforating of steel elements must be taken into consideration.

Equally important the subject of anchoring bolt installation when after installation embedded parts offset or wrong elevation appear because of mistakes during setting of threaded protection. This errors must be fixed before concrete gushing. Also columns anchored or welded not tight enough influence not only steadiness of construction but also performance in case of fire. Cage welding should be applied in this case in the row with fire protective coatings. (7) Identically, use of as thin elements in places of joints as possible will prolong reliability.

Next key factor is welding. It is essence activity while manufacturing and assembling construction of a building. It gives high level of freedom for designer unalike to bolted joints. Qualification of workers performing welding determine lifelong of the construction. Figure 3 shows stages of quality and performance control of welding process during the whole production period.

Figure 3. Information required to ensure weld quality and performance. (8)

Inspection and testing of welded parts is required process which could be performed by destructive and non-destructive methods. Non-destructive method consists mostly of visual inspection, but also could include ultrasonic testing (UT), magnetic particle inspection (MPI) and rarely radiographic inspection. Nevertheless, the last method is more complicated in terms of time and possibility to affect health.

Resilience of steel decrease rapidly when undergo temperatures below zero, it become fragile. While welding under low temperatures suitable steel with high strength should be chosen. Welded joints shouldn’t create closed shapes, doted joints must be avoided as well as clusters to prevent increase of tension on sector. During welding in conditions of low temperatures it is important to avoid gassing of weld as well as provide preliminary and concomitant heating of welding area. (9) Weld crossing should be avoided where possible. Snow and ice must be cleaned from detail before welding.

Next valuable issue that can cause deterioration of steel construction, but, nowadays, excluded out of designing residential buildings is corrosion. Owing to galvanized steel and zinc coating inside steel decking and light steel infill walls an internal atmosphere, created by external insulation and cladding system, protects from weather and other factors. It was found after observations of 20 years, that zinc loss of 0.5 g/m2 per year is commensurate with the calculated lifetime of a building of over 200 years. (7)

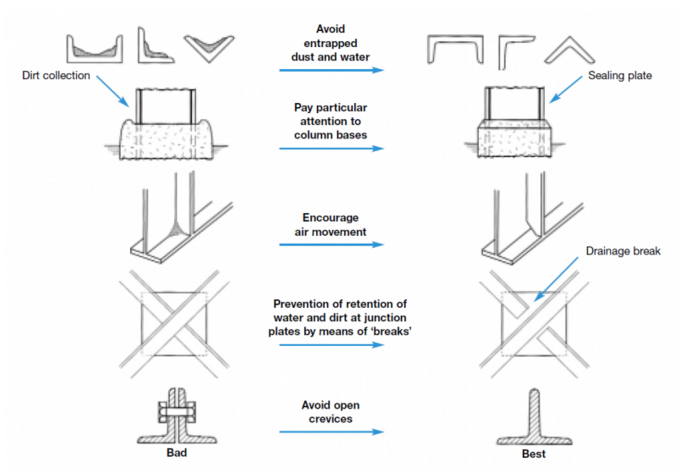

Figure 4. Some best practices to keep in mind when designing steel structures. (10)

Figure 4 also shows some ways to protect future building construction moisture and debris trap sectors from corrosion. Intricate shapes usually hard to protect meaning they are first to deteriorate. Entrapment of humid and dirt in small gaps, hard to reach corners and obscure surfaces represent the threat of corrosion formation. Moreover, inspection and coating procedure in such places are importantly challenging. And if approach to latter maintenance is impossible unattended sections could cause unexpected damages of construction. Selection of the coating determine the level of protection from corrosion as well. Wrong or inefficient choice may provoke irreversible pernicious changes of material.

High risk of corrosion occur in places of junction of different materials. Unavoidably, steel elements of construction interact with parts made of other materials. This places must be cautiously verificated for corrosion safety. Conjunctions of different metals should be avoided if possible. Otherwise proper insulation must be applied in such spots in order to avoid bimetallic corrosion. If structural steelwork enclosed in concrete the quality of latter and sufficient layer of cover ensure lifelong of particular connection. Timber elements of construction in places of connection with steel parts could cause moistness and must be separated by plastic sheets. (11)

Damages of parts of steel structure especially in external or wet environment often take place while transportation and/or erection. Elements of construction exposed to damage must be carefully checked and replaced if needed. The erection strategy should be planned during the design stage. To increase the speed of construction and to lower risk possibility during building site works should be scheduled upfront. It is important to consider that planning of assembling in the factory of major quantity of build elements will save money reserved for contractors and time which in terms of bad weather conditions could prolong lifespan of future building.

There are several ways to avoid listed aspects. First of all, construction material must be checked for presence of cavities, crevices, etc. Touching the construction, welded joints are preferred to bolted joints and seal lap joints should be avoided. Also drainage holes for water should be implemented as well as arrange of free circulation of air around the structure by creating vent-holes and drain-holes in order to prevent dry out of steel.

Date: 2015-12-18; view: 723

|